Nội dung

What is zero liquid discharge (ZLD) technology?

Zero liquid discharge (ZLD) is a process that creates many benefits for petrochemical plants, industrial production and environmental activities that generate large volumes of wastewater. Because ZLD saves on liquid disposal costs and there is no liquid waste in the production process.

Each technological process involved in the ZLD process plays an extremely important role. The goal is to create the final product of ZLD as solid crystals.

ZLD typically includes:

- Pre-treatment processes to reduce part of the concentration of pollutants such as COD, BOD, hardness, TSS, Ammonium, ….

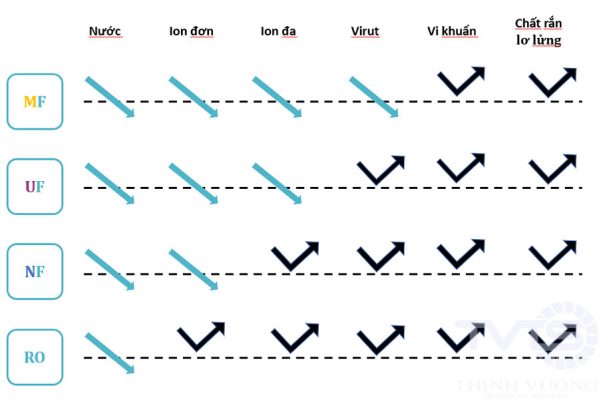

- Next is the MF/NF/UF ultrafiltration membrane technology and RO membrane. Helps to recover clean water and create a concentrated stream to the evaporation system.

- Evaporation technology is vaporization and condensation to recover water. The higher the concentration of dissolved substances in the water, the greater the water recovery efficiency. Therefore, evaporation technology is often placed after the membrane filtration technology.

- The waste after evaporation technology will be passed through drying technology to dehydrate and create solid crystals.

- The final water is recycled to the ZLD process.

Describe some technologies applied in zero liquid discharge (ZLD).

Pre-treatment technology.

Pre-treatment technology, also known as physicochemical technology/traditional technology, is generally a water treatment stage. In which there is at least the participation of 02 water treatment methods.

Based on the characteristics of wastewater and the input limit requirements of the RO system in the ZLD process, appropriate water treatment methods are applied.

Some water treatment methods commonly used in water treatment are: flotation (DAF); physicochemical; Fenton; Stripping; biological (microbiological) methods; …

Ion exchange technology in Zero liquid discharge (Ion exchange).

Ion exchange technology solves problems in water treatment effectively and economically. Usually this technology is used in the water treatment process with low solute concentrations.

Then it will be easy to remove and treat the polluting components in the water. Helps to recover maximum clean water, easily meeting current discharge standards.

In the ZLD process, ion exchange technology is often used after RO. When the water is reused after treatment, it has high and very high standards for the EC index in water. Some industries such as: thermal power, electronics, medical, pharmaceutical, …

Applying RO/NF/UF/MF membrane technology for Zero liquid discharge.

RO/NF/UF/MF membrane technology has proven its effectiveness worldwide. Applications in the fields of clean water treatment, drinking water filtration, wastewater and seawater treatment.

ZLD solution was born, from which RO/NF/UF/MF technology was strongly applied in industries. In particular, some countries apply RO and evaporation technology in the production of fresh water from seawater, recovery and production of refined salt.

With the values that RO membrane technology brings, we need to understand more clearly about the standards of the membrane to be able to meet in the ZLD process.

Some requirements for RO/NF/UF/MF membranes in the ZLD process:

- Ability to withstand high organic loads and high concentrations of total dissolved solids (TDS).

- Ability to withstand high pressure.

- Organic, inorganic and biological substances on the membrane surface should not be too high to increase membrane life.

- Cost savings in investment and operation to reduce the load on the evaporation system.

- Large clean water recovery capacity, creating a concentrated stream entering the evaporation system with high concentration. Improve the evaporation efficiency of the evaporation system.

- Compact installation area, easy to upgrade capacity, creating flexibility in production.

Some recommended filter membrane product lines:

- STRO open channel reverse osmosis membrane.

- ROCHEM RO membrane: PFRO, TSRO, HPRO series, …

- Unisol, WTA German membrane specialized for wastewater reuse and ZLD.

- DOW FILMTEC BW Series RO membrane: used for water supply or brackish water.

- DOW FILMTEC ECO SERIES RO membrane.

- DOW FILMTEC SW series RO membrane: used for wastewater or seawater.

- TORAY RO membrane.

Water evaporation technology applied in zero liquid discharge process.

Evaporation technology works on the physical principle of vaporizing the solution. The result of the process is that the vapor is condensed into clean water and solids.

On the principle of providing heat energy to convert from liquid to vapor. The evaporator operates based on two factors: the method of supplying or recovering heat energy and the method of heat exchange in the device.

In the zero liquid discharge process, evaporation technology plays a role in converting the solution to be treated into a slurry or solid form. The treatment efficiency of the evaporator depends on the concentration of dissolved substances in the solution. The more concentrated the concentration, the more effective the evaporation.

Bên cạnh đó, Công nghệ RO cho tỉ lệ thu hồi nước sạch cao, dòng thải bỏ sau RO đậm đặc với nồng độ chất tan lớn. Do đó, thiết bị bay hơi thường được thiết kế nằm sau hệ thống màng RO.

Sludge drying creates the final product of the ZLD process.

Sludge drying is a water treatment step by evaporating water in the sludge. The drying process significantly reduces the volume and weight of the sludge. This makes it easier to collect, transport, and reuse solid waste after the water treatment process.

Depending on the dryness level of the sludge, choose the appropriate drying method. Currently, there are many types of sludge drying products on the market, but in general, they operate under the following general principles:

- Direct drying by heat.

- Indirect drying through intermediate materials.

- Infrared drying.

Some other sludge drying methods.

- Sludge drying by creating a closed chamber space and allowing air to move convectionally. The principle of continuous sludge drying is due to air convection.

- Preliminary drying and molding of sludge. Then dry directly with a dryer. Utilize the heat of the outer part of the sludge block to maintain heat and dry the inner part, saving heat energy for the drying process.

- Applying renewable energy in sludge drying by greenhouse sludge drying method.

The final stage of the ZLD process also applies a number of other solid drying and crystallization methods such as:

- Crystallization drying using biological ponds/lakes.

- Solar dryer: saves energy but takes up a lot of space.

Zero liquid discharge not only creates solid crystalline sludge for disposal. ZLD also applies many technologies of vaporization and crystallization of solids at different temperatures. From there, materials that can be reused for the production process can be recovered.

Some materials that can be recovered from the water treatment process are: NaOH, Na2SO4, K2SO4, gypsum, …

Survey of high recovery water treatment technology and Testing the water recovery ability of RO ROCHEM membrane technology for zero liquid discharge solution.

RO ROCHEM reverse osmosis membrane technology was born in the 1970s, serving the treatment of seawater for the navy. Developed through many stages, RO ROCHEM is a pioneer in the application of membrane technology for wastewater treatment and reuse.

ROCHEM has developed membrane technology into many product lines with different treatment segments. TVTS tested the ability to recover clean water that meets reuse standards with ROCHEM RO membrane modules at several factories in Vietnam.

Strengths of ROCHEM RO membrane technology.

- Reuse water source.

- High recovery, up to 95%.

- Completely remove color.

- No chemicals/ Very little chemicals used for pre-treatment.

- Limit clogging.

- Technology has been proven effective worldwide.

- Total investment and operating costs are lower than treatment systems with the same flow rate.

- High life of the membrane system.

- Compact treatment system, flexible installation location, does not require too large an area.

- Easy to install, upgrade capacity, maintain and replace.

- Can treat wastewater containing very high levels of COD, BOD, Nitrogen, Ammonium.

- Ensure optimal operating costs, low total operating costs for the entire product life cycle.

The pilot projects have all been deployed and put into stable operation.

You are wondering about choosing water treatment technology for the ZLD system at your factory. Please connect with us to discuss and choose the product lines and technologies suitable for the production process at your factory.

TVTS will meet the requirements you set out with the motto of WIN-WIN cooperation. Your business development is our development.

Related articles.

Some regulations on Zero liquid discharge.