Nội dung

- 1. Overview of RO membranes

- 2. How is the structure and operation of the RO membrane module?

- 3. How many types of RO membranes are there?

- 4. Applications of RO membranes in industry

- 5. Instructions for use, maintenance and maintenance of RO membranes

- 6. Cleaning and anti-scaling chemicals for RO membranes

- 7. Refer to the latest industrial RO water filter membrane price in 2024

- 8. Some issues related to RO membranes

1. Overview of RO membranes

What is an RO membrane? RO membranes are devices used to filter clean or purified water from different water sources. They are capable of removing most of the components in natural water, viruses, bacteria. Creating clean mineral water or high-quality purified water depending on the purpose of use.

The English name of RO membrane is Reverse Osmosis Membrane, which means reverse osmosis membrane. It was invented in the 50s by scientist Oragin. RO membranes were fully developed and widely applied since the 70s of the last century.

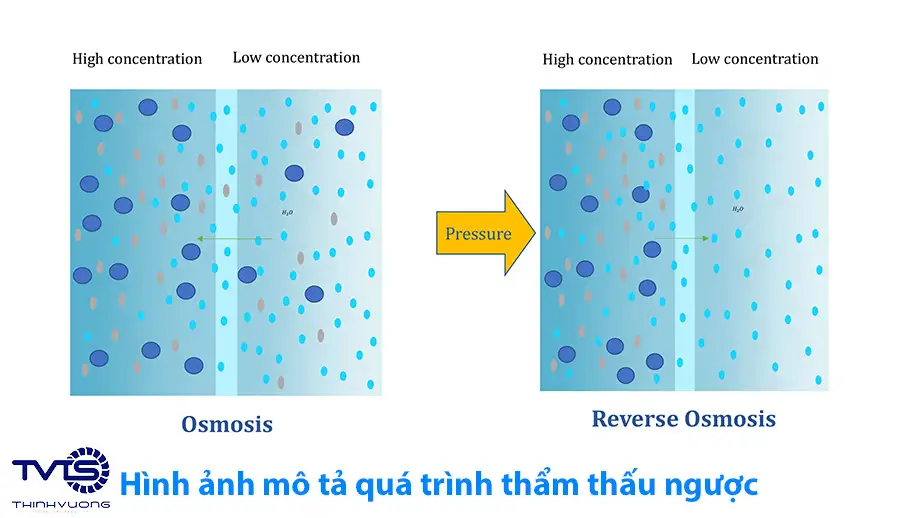

True to their name, RO membranes operate based on the physical principle of “reverse osmosis”. Osmosis is the process of water molecules moving through a semi-permeable membrane from a place with a low concentration of solutes to a solution with a higher concentration of solutes. The purpose is to balance the concentration of solutes in the solution. Reverse osmosis is to reverse the osmosis process by using pressure. Helps to obtain solutions with gradually lower solute concentrations.

RO membranes are mostly made of Polyamide material. Initially, they were used in the marine and naval fields. Later, when the demand for clean water increased, RO membranes began to be used more in industrial and daily life fields.

2. How is the structure and operation of the RO membrane module?

Are you interested in the structure of the RO membrane?

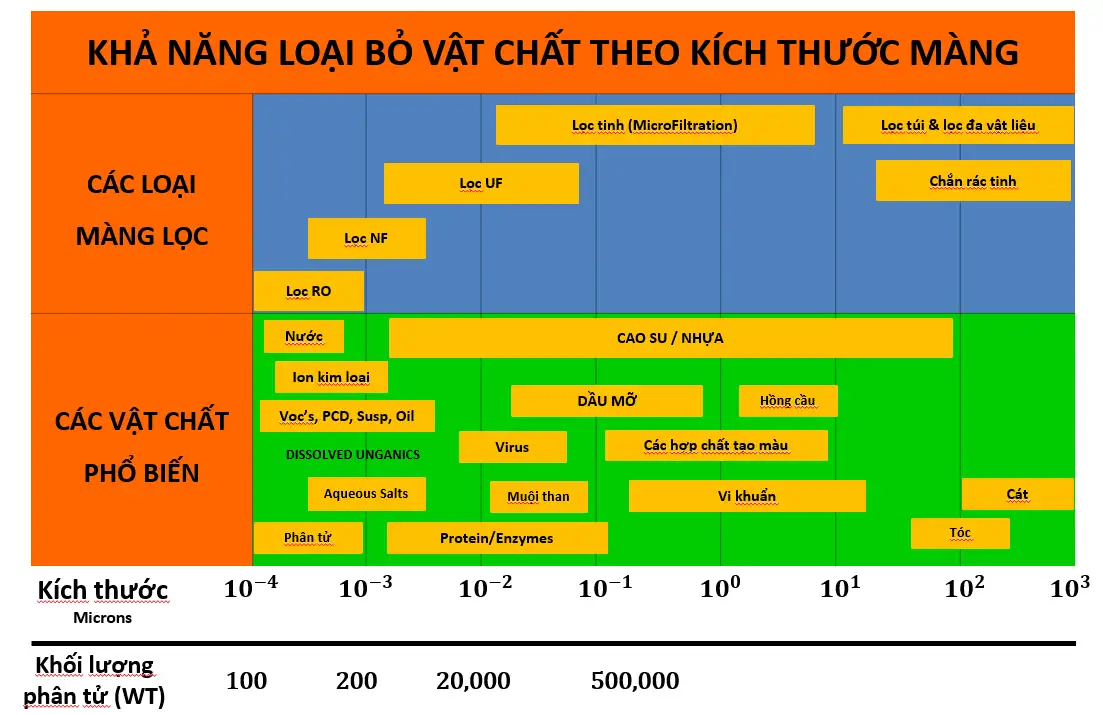

The RO membrane is made of Polyamide material as a semi-permeable membrane. This membrane is woven with filter holes with sizes from 0.0001 to 0.001 µm. At this size, only water molecules are allowed to pass through.

During use, RO membranes often appear in the form of RO membrane modules. The module is a device with a tight arrangement between the filter membrane and the membrane shell (to protect the membrane). It is also equipped with accessories to lead water into the membrane to process and recover clean water after filtration.

2.1 Structure of RO membrane module

In terms of shape: RO membrane module is usually cylindrical, can be placed vertically or horizontally.

In terms of structure: RO membrane modules from different manufacturers will have different membrane arrangements and structures. However, in general, each RO membrane module will include:

- Centering shaft: here the clean water after filtration is collected and almost out of the membrane module.

- RO membrane: membranes are usually arranged in two main forms: spiral (wrapped around the centering shaft); or disc (stacked with the center of the disc coinciding with the center of the disc).

- RO membrane shell: is a cylindrical or semi-cylindrical tube, made of plastic, paper plastic or stainless steel. The membrane shell has the effect of fixing the membrane arrangement inside. At the same time, it protects the membrane layer from physical and chemical agents.

2.2 How the RO membrane module works

As mentioned before, the reverse osmosis process takes place by applying pressure to the input water (the solution to be filtered). Under the influence of pressure, pure water molecules will be pushed through the RO membrane and recovered.

The components in the water include: dissolved salts, organic and inorganic substances, bacteria, viruses, suspended solids, grease, etc., which are collectively called substances

These substances, according to physical principles, cannot pass through the membrane, are removed from the module and are led into the wastewater section (concentrated stream after RO). After the process, the purified water can be used immediately. Depending on the purpose of use, the clean water obtained may need to be further treated to ensure the standards of use.

However, the input water of the RO membrane system needs to be pre-treated. It can be by physical and chemical treatment methods, microbiological treatment, sand filtration and fine filtration (coarse filter core). This helps ensure that the input water of the RO system is within the allowable treatment threshold. Thereby, helping to improve the filtration efficiency in terms of quality and clean water recovery rate.

3. How many types of RO membranes are there?

Today, there are many types of RO membranes on the market. They can be classified based on factors such as: Capacity, purpose of use, manufacturer, origin, etc. However, TVTS will classify RO membranes according to the field of application. Including two main types: industrial RO membranes and RO membranes for drinking water purifiers, household water purifiers.

RO membranes are also used for desalination, filtering seawater into fresh water, and treating brackish water. However, in this field, not only RO membranes can be applied, but there are also other types of membranes that do well, such as UF, NF, MF membranes, etc. Therefore, we will only focus on classifying RO membranes in the industrial and life fields.

3.1 RO membranes used in industry

In industry, RO membranes are used to produce clean water for production from water sources supplied to factories. Or used to treat wastewater in factories and industrial zones. The purpose is to recover clean water that meets discharge standards to reuse/recycle wastewater for the production process.

Popular types of industrial RO water filter membranes today include:

- ROCHEM RO Membrane (Germany)

- Dow Membrane (USA)

- Vontron Membrane (USA)

- Filmtec Dupont RO Membrane (USA)

- Dupont Membrane (USA)

- Toray Membrane (Japan)

- GE Membrane (USA)

- Keensen Membrane (China)

- Lanxess Membrane (Germany)

- Pentair Membrane (Composite housing to accommodate different membrane modules)

- Nitto Denko Membrane (Japan – Hydranautics)

- LG Chem Membrane (Korea)

3.2 RO membrane for drinking water purifiers, household water purifiers

Household water purifiers or drinking water purifiers often use RO membranes that can retain a certain amount of minerals for users. In addition, they will be designed to be compact and have low capacity. For users to easily disassemble, replace and transport.

Some brands/RO membranes are used for home water filtration equipment. Such as:

- Kangaroo RO water filter

- Karofi water filter/membrane

- Aqualast water filter

- Aqua water filter

- Sunhouse water filter

- Vortex water filter

- Nitto Denko RO membrane

- Vontron RO membrane

- Rotex RO membrane

- Mutosi membrane (Korea)

TVTS is a research, application and technology transfer unit in the field of water and wastewater treatment. We provide products and consulting services and provide solutions for water and wastewater treatment with the goal of circulating, reusing and further not discharging liquid.

Therefore, our products mainly serve the industry, so the following content we will focus on the application of RO membranes in industry.

Refer to the leading RO membrane products at TVTS: products applied for circulating and reusing wastewater.

4. Applications of RO membranes in industry

RO membranes are widely and diversely applied in many different water treatment purposes. They can participate in industrial processes such as:

- Water filtration systems for manufacturing industries that require input water of higher purity than tap water. For example: food, pharmaceuticals, soft drinks, thermal power, electronics, etc.

- Industrial wastewater treatment systems.

- Wastewater treatment systems for special industries such as textiles, paper, chemicals, leather, electroplating, electronics, hospitals, pharmaceuticals, food, etc.

- Drinking and domestic water systems for residential areas, living areas for workers at production facilities.

- Wastewater circulation and reuse systems in most manufacturing and industrial plants.

5. Instructions for use, maintenance and maintenance of RO membranes

5.1 How to read and understand the parameters of industrial RO membranes

5.1.1 RO membrane module size

Each manufacturer will produce each line of membrane modules with different sizes. The module size will depend on the structure of the RO membrane fibers, design, …. However, on the market today there are some common and popular membrane module sizes such as: 4021, 4040, 8040, …

When encountering an RO membrane module with a size described as 8040, we will understand that: the membrane module has a filter membrane length of 40 inches (1016mm), diameter of 8 inches (203.2mm).

5.1.2 Flow

Flow is usually represented by:

- Maximum Flow

- Inlet Flow

- Outlet Flow

Flow units: GPD (Gallon per day), LPH (Lit per hour) are commonly used units.

5.1.3 Water treatment capacity

The water treatment capacity of an RO module is considered through the following indicators:

- Demineralization capacity (%): approaching 100% is the highest.

- Allowable input TDS (ppm): the higher the capacity to treat polluted wastewater, the greater the capacity to treat polluted wastewater.

- Recovery rate (%): the capacity to recover clean water after treatment, approaching 100% is the highest.

5.1.4 Maximum and operating pressure

The maximum operating pressure of current RO membrane lines is usually 150psi and 225psi. Besides, there are still some product lines that allow this pressure to be up to 1000 psi.

5.2 Some issues related to the operation and maintenance of the RO membrane system

When to clean the RO membrane

When to replace the RO membrane module

Instructions on how to replace the RO membrane

How to install and replace the RO membrane filter module

6. Cleaning and anti-scaling chemicals for RO membranes

During the production process, the RO membrane needs to be checked and cleaned regularly. This helps maintain the efficiency of water treatment and increase the life of the system. To clean the RO membrane, 4 groups of chemicals are needed: acid group, alkaline group, oxidizing group and anti-scaling group.

[Scale on RO membrane]6.1 Chemicals for RO membranes – Acid cleaning chemicals

Used to remove inorganic residues and heavy metals such as calcium, magnesium, etc. Citric acid and acetic acid are commonly used.

Acid RO membrane cleaning chemicals “Cleaner B”. Outstanding ability to remove inorganic residues and heavy metals for RO membranes in wastewater treatment. Made in the Netherlands.

6.2 Alkaline cleaning chemicals

Used to remove organic substances such as grease, microorganisms. NaOH, an anionic surfactant is a commonly used ingredient.

Alkaline RO membrane cleaning chemical “Cleaner AA”. Ability to completely remove organic matter and grease for RO membranes in wastewater treatment. Origin: Netherlands.

6.3 Medium acidic oxidizing cleaning chemical

Used to remove inorganic residues and iron oxides. Chlorine, hydrogen peroxide, ammonium are some common chemicals. (Refer to RO membrane cleaning chemical “Cleaner C”).

Oxidizing RO membrane cleaning chemical “Cleaner C”. Ability to completely remove inorganic matter and iron oxides for RO membranes in wastewater treatment. Origin: Netherlands.

6.4 Anti-scaling chemical on membrane

Used to prevent scaling on RO membranes. This scaling can be the growth of bacteria and moss, inorganic ions, silica salts, Ca2+, …. PCA (Phosphino Carboxylic Acid) is an anti-scaling ingredient for Ca2+. In addition, triclosan is a compound used to fight bacteria. (ROPREP anti-scaling chemical)

ROPREP anti-scaling chemical for RO membranes. Good anti-scaling for RO membranes in wastewater treatment. Made in the Netherlands.

Note: When using chemicals to clean RO membranes, operators must strictly follow the manufacturer’s instructions. At the end of the cleaning process, ensure that there is no chemical residue left on the RO membrane. At the same time, make sure you are using the right type of chemical suitable for each specific type of filter membrane. Avoid damaging the membrane and reducing the efficiency of the filtration process.

7. Refer to the latest industrial RO water filter membrane price in 2024

The price for industrial RO membranes ranges from 7 million VND to several tens of millions of VND for low-pressure membranes. And the price ranges from 10 to hundreds of millions of VND for high pressure membranes. We have mentioned the reference prices of some models of each brand at “Refer to the price list of industrial RO membranes 2024”.

8.1 Is the saltwater filter membrane an RO membrane?

The answer is yes. Usually they are called seawater RO membranes. Besides, there are also some types of water filter membranes that can filter saltwater into fresh water. Or filter seawater, desalinate other such as: UF membrane, NF membrane, ….

8.2 Is the rough filter core an RO membrane?

The rough filter core is not called an RO membrane. This is a type of filter core made of many types of fibers with different compositions. They are used to filter substances larger than 1 µm or up to tens of µm. Usually used before the RO membrane system in industrial processes.

8.3 Instructions on how to identify a poor quality RO membrane

In today’s competitive market. Having experience in distinguishing between real and fake RO membranes. Or how to ensure the quality of RO membranes is very necessary. We will review some ideas that readers can refer to, such as:

- Check the product certifications: Genuine RO membranes are often provided by the manufacturer, so the goods need to have clear CO, CQ. It is necessary to request a valid invoice with the product name to verify that the goods are imported and traded clearly.

- Check the price: Quality industrial RO membranes often have relatively high prices due to the use of good technology and materials. If you see a product with a fairly cheap price, it may be a fake RO membrane.

- Conduct an experiment to check the water quality: Use a handheld water quality testing device to check the cleaning performance of the RO membrane.

- Check the membrane surface: Genuine RO membranes often have smooth and even surfaces, while fake RO membranes may have cracks, pitting or unevenness.

Above are some ways to check if RO membrane is real or fake. You can also consult an expert on this issue for better verification methods.