Nội dung

- 1. What is a wastewater reuse system?

- 2. Wastewater reuse system in production sectors

- 3. Some water treatment technologies and equipment are used in the process of treating reused wastewater.

- 4. Typical wastewater reuse treatment technology process applied by TVTS.

- 5. Reputable contractor providing wastewater reuse services and systems in Vietnam

1. What is a wastewater reuse system?

1.1 Description of wastewater reuse system

To describe the wastewater reuse system, we first need to know “What is wastewater reuse?”?

Wastewater reuse is the process of cleaning wastewater and used water and reusing them for a specific purpose. This must ensure that clean water standards and regulations are met.

So, “Hệ thống tái sử dụng nước thải sẽ là hệ thống xử lý nước thải, bao gồm các thiết bị, quy trình xử lý nước và quy trình sản xuất sử dụng nước. Quá trình xử lý nước thải tạo ra chất lượng nước sau xử lý đạt tiêu chuẩn để tái sử dụng”.

Reuse is the use of waste water for different purposes. Sometimes the water for reuse does not have to be completely clean. It only needs to be of sufficient quality for reuse in some production stages.

In general, the wastewater reuse system will include a system of machinery, equipment and water treatment methods. Designed and planned for specific construction and operation processes. Required to achieve the set goals for reuse.

1.2 Requirements for a wastewater treatment system that meets reuse standards

The characteristics of a wastewater reuse system or wastewater reuse technology process are:

- Pre-treatment wastewater treatment technology (Physical and chemical level 1 or level 2, Ozone).

- Combined with filtration through materials (multi-layer filter, carbon filter, sand filter, fine filter core tank).

- Next is RO reverse osmosis membrane technology.

- Or UF, MF, NF membranes can be used depending on the quality of water after treatment.

- Disinfection by UV or specialized disinfectants, pH adjustment.

- If ultra-pure water quality is required, ion exchange technology will be used

The difference between a conventional wastewater treatment system and a reuse system is the quality of the output clean water. In addition, when building a general wastewater treatment system, investors need to pay attention to the following characteristics to make the right choice for their factory.

1.3 Characteristics of a modern wastewater treatment system, it is necessary to have:

- The investment cost is not too high, but not too cheap. Because value always goes hand in hand with quality

- Save installation space.

- Training for operators, technology transfer. Avoid dependence on the contractor.

- The system can easily upgrade capacity and water quality.

- Simple operation, maintenance and repair. Automatic, remote and modern control.

- The system is easy to open and close, does not consume much energy when the system stops or has problems.

- The water after treatment meets the reuse standards and is used for at least one purpose.

2. Wastewater reuse system in production sectors

2.1 Reuse of cooking and washing wastewater in the textile dyeing industry

Reuse of wastewater does not mean that the final wastewater must be treated to meet the standards for use. In the textile dyeing industry, wastewater can be treated in the middle of the production process for immediate reuse. Increase the value of use and exploitation of water.

For example, wastewater after the 3rd and 4th washes can be pre-treated and then reused in the 1st or 2nd wash.

In addition, with current water treatment technology. Allows the treatment of textile wastewater to meet the standards for production circulation. The treated water exceeds drinking water standards.

2.2 Application for food wastewater reuse

In the process of producing dried food. Wastewater during the production process will be cleaned and reused in the cutting, trimming, and washing of sand and soil from input materials.

HACCP (Hazard Analysis Critical Control Point) is a system for managing hazards and risks to product quality in the food industry. Applying HACCP will evaluate the quality of water to ensure microbiological safety and allow for different purposes when reusing water in the food industry.

3. Some water treatment technologies and equipment are used in the process of treating reused wastewater.

- RO membrane

- UF membrane

- NF membrane

- Chemical treatment process

- Biological treatment process

- Ion exchange metho

4. Typical wastewater reuse treatment technology process applied by TVTS.

In most of the technological processes of the wastewater reuse system that TVTS consults and provides. We consider applying TSRO membrane technology to the treatment process. Specifically:

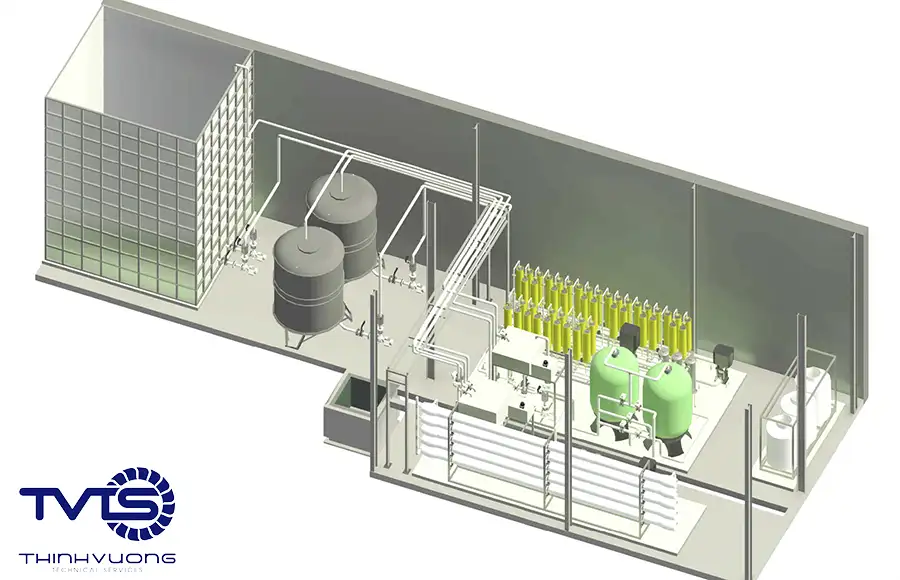

4.1 Technological process of a typical project that TVTS implemented in 2023.

Technological process of implementing a wastewater reuse system for a specific customer. Implemented and completed by TVTS in 2024.

Description of technological process from technical explanation of coffee production wastewater reuse project, capacity 500 m3/day and night.

Input wastewater stage

- Wastewater groups will be collected into a common tank.

- Called the inlet tank of the STRO system. The inlet tank has an air distribution system inside. Wastewater here is supplied with air from the factory’s blower.

Processing stage by STRO system

- The wastewater will be initially filtered to remove particles larger than 50 microns. Then it goes through another filter to remove particles larger than 10 microns.

- The pre-filtered water is fed into the Spacer Tube Reserve Osmosis (STRO) system. STRO is designed to recover 82% of clean water. STRO includes a high-pressure pump system and parameter control devices. The complete system is controlled by PLC.

- F1 clean water is recovered after the STRO system at the storage tank and further treated by the SPRO system to ensure output requirements.

Processing stage using SPRO system

- F1 clean water is treated with the Spacer Wound Reserve Osmosis (SPRO) system. SPRO is designed to recover 90% of clean water. SPRO includes a high pressure pump system and parameter control devices. The complete system is controlled by PLC. F2 clean water will achieve the following indicators:

| Sr.No | Parameter | Unit | Permeate Requirements |

| 1 | Capacity | m3/h | 500 |

| 2 | Conductivity | µS | 25 |

| 3 | TDS | mg/l | 12 |

| 4 | COD | mg/l | 80 |

| 5 | BOD | mg/l | 40 |

| 6 | TSS | mg/l | – |

| 7 | Hardness | mg/l CaCO3 | – |

| 8 | Silica | mg/l | 1 |

| 9 | Chlorides as Cl | mg/l | 6 |

| 10 | Colour | Pt-Co | No colour |

| 11 | Total N | mg/l | – |

- After the SPRO system, clean F2 water is led to the tank and used for required purposes.

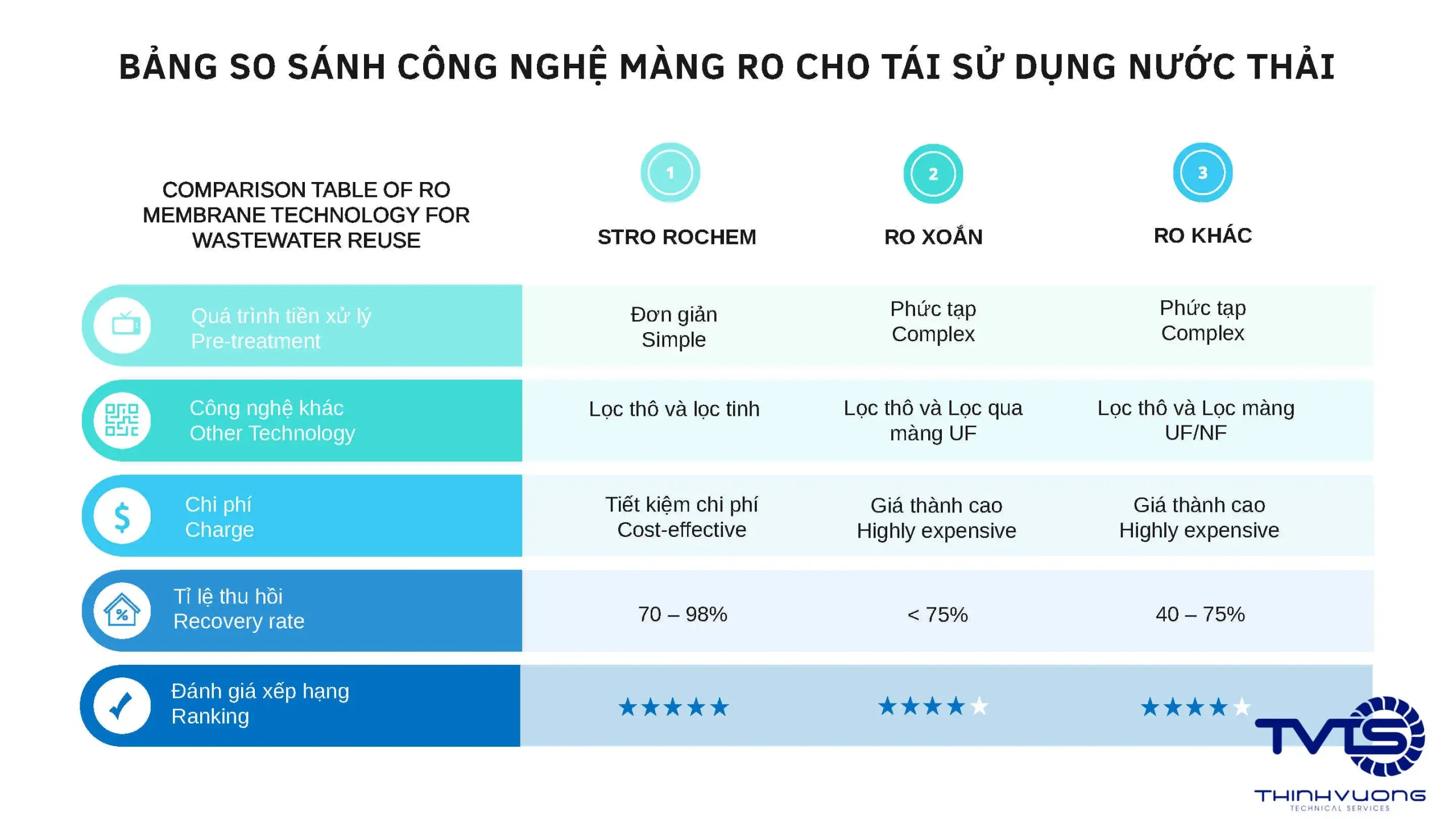

4.2 Distinguishing the technological process of wastewater reuse between conventional RO membrane and STRO membrane at TVTS.

For conventional RO membrane (spiral RO membrane), the wastewater reuse process is: Pre-treatment => Rough filtration => UF => Spiral RO/SPRO

For STRO membrane, the process is: Pre-treatment => Rough filtration => Fine filtration => STRO. Wastewater reuse is completed and put into operation at the factory

Compared to conventional RO membranes, the wastewater reuse technology process using STRO membranes is more cost-effective. Instead of having to invest in two membrane filtration systems, UF and RO, using only one TSRO membrane system is enough.

5. Reputable contractor providing wastewater reuse services and systems in Vietnam

Thinh Vuong Technical Services Joint Stock Company (TVTS) is a reputable EPC contractor in Vietnam, specializing in providing solutions for wastewater treatment and wastewater reuse. With more than a decade of experience, TVTS is proud to meet customer requirements, providing effective solutions and reducing costs in investment and operation.