Applying evaporation technology to hazardous waste treatment (wastewater) helps save up to 70% of operating costs for the factory. Improve production efficiency, quick capital recovery time.

Nội dung

- 1. Project Introduction

- 2. General project requirements

- 3. The problem of operating costs

- 4. Proposed processing technology

- 5. Technological process of economical hazardous waste (wastewater) treatment plan

- 6. Analysis and solution of the problem of reducing operating costs for pesticide factories

- Summary:

1. Project Introduction

- Project name: Hazardous wastewater treatment plan.

- Location: Bien Hoa Industrial Park, Bien Hoa City, Dong Nai Province

- Customer: Plant protection product supplier

2. General project requirements

The current situation at the pesticide factory is generating a large amount of hazardous liquid waste from production activities as follows:

- Production tank cleaning water/daily;

- Production floor cleaning wastewater/daily;

- Wet scrubber water (NaOCl) absorbs and treats exhaust gas/6 months of cleaning, change water/time;

3. The problem of operating costs

The maximum monthly wastewater capacity from the factory is 18 m3/month. With the cost of treating hazardous wastewater from external units near Bien Hoa Industrial Park according to data from TVTS customers is about ~ 6.0 – 7.5 million VND/1 m3 of wastewater, thus leading to the factory’s monthly cost of treating this source of waste is very large (On average, about ~ 108 – 135 million VND/1 month).

4. Proposed processing technology

Faced with the given problem, TVTS proposes a treatment plan to minimize the amount of liquid waste generated above, while optimizing production costs as follows:

4.1 Economical hazardous waste treatment technology 2024

- Applied technology: evaporation technology

- Equipment name: Heat pump vacuum evaporation system.

Vacuum evaporation is a process of condensing, evaporating water using vacuum pressure. The condenser operates at vacuum pressure (less than atmospheric pressure) with the aim of reducing the boiling point of the concentrated solution.

The coefficient of performance (COP) is the ratio of useful heat or cooling delivered to the work required by the equipment. This concept is often used for refrigeration, air conditioning or heat pumps. If the consumed energy is converted directly into useful heat or cooling with an efficiency of 100%, then the coefficient of performance COP = 1. A higher COP means higher efficiency, lower energy (electricity) consumption and therefore lower operating costs.

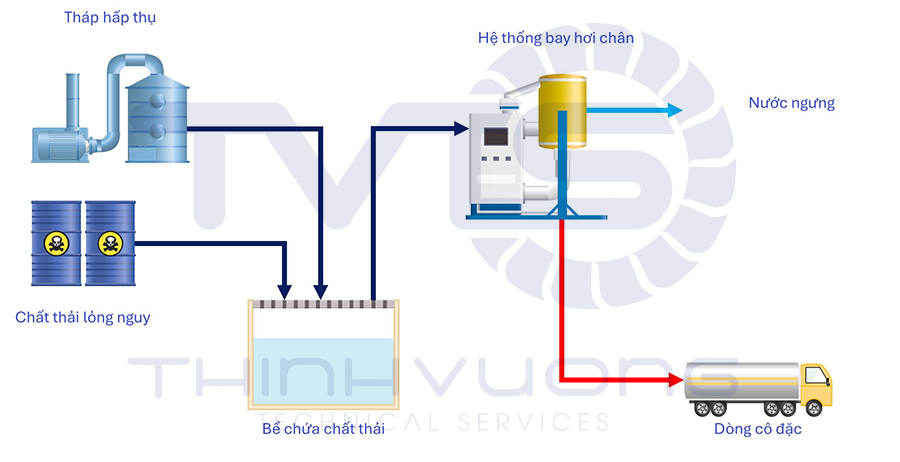

HPVE system technology diagram

4.2 Heat pump vacuum evaporation system (HPVE)

HPVE uses the same principle as refrigeration, air conditioning or heat pumps. Heat pump vacuum evaporation system when operating stably will have a coefficient of performance COP of about 3.0 – 4.5, with the following advantages:

- The energy cost (electricity) for the evaporation process is low, with only about 140 – 160 kW of electricity for 1 m3 of condensate when compared to direct evaporation (About 540 – 600kW/m3) or using steam (400 – 1,100 kgSteam/m3).

- The system does not need to consume steam, hot water or fuel and operates only on electricity, the evaporation process will also cool the condensate without the need for a cooling tower.

- Wastewater can be evaporated at very low temperatures (30 – 40oC), so the equipment can be applied to many types of wastewater with concentrated properties or containing substances sensitive to temperature.

- The air compressor used for the HPVE system has a similar design to the air compressors used for air conditioners, heat pumps … with reasonable costs due to mass production, which also makes maintenance, repair and replacement easy.

- The system can operate intermittently or in batches.

5. Technological process of economical hazardous waste (wastewater) treatment plan

Proposed technology solution:

6. Analysis and solution of the problem of reducing operating costs for pesticide factories

6.1 Current solution: Collect and hand over to an external third party for direct processing

- Treatment cost when handing over to an external unit: 7,500 VND/Liter (Kg)

- Maximum monthly discharge volume: 18 m³

- Estimated maximum total monthly operating cost:

7,500 × 18,000 = 135,000,000 VND/Month

- Estimated maximum annual operating costs:

135,000,000 × 12 = 1,620,000,000 VND/Year (*)

6.2 Proposed solution: Treatment by TVTS heat pump vacuum evaporation system

- Estimated investment cost for this treatment item: 2,000,000,000 VND (For a design capacity of 700 liters/day or 21 m3/month)

- Operation cost for a maximum m3 of wastewater: 400,000 VND/m3 (Including electricity and maintenance and repair costs)

- The cost of treating the concentrated stream of the system for a m3 of concentrated stream is: 7,500,000 VND/m3. The system is designed with a recovery rate of > 90%.

- Estimated system depreciation cost:

2,000,000,000 / 10 years / 12 months / 18 m³ = 925,000 VND/m3

- Maximum monthly discharge volume: 18 m³

- Maximum total monthly operating costs:

(400,000 + 925,000) × 18 + 7,500,000 x 18 x 10% = 37,350,000 VND/Month

- Estimated maximum annual operating costs:

350,000 × 12 = 448,200,000 VND/Year (**)

- Estimated maximum factory cost savings when investing in TVTS system:

620,000,000 (*) – 448,200,000 (**) = 1,171,800,000 VND/Year

- Payback period of the system compared to current options:

2,000,000,000 / 1,171,800,000 = 1.7 Years

Summary:

In the case of a pesticide factory, TVTS has provided a solution to reduce costs by more than 70% and optimize the production process. In addition to evaporation technology, TVTS also provides many other innovative solutions suitable for each story and problem of each factory. Tell us why you need us, and TVTS will accompany you throughout the development journey of the factory.