Solutions » Xử lý nước thải công nghiệp » Rubber Industry Wastewater Treatment: Technology & Effective Solutions

Nội dung

1. Introduction to Rubber Industry Wastewater

Ngành công nghiệp cao su đóng vai trò quan trọng trong nền kinh tế, nhưng cũng tạo ra lượng lớn nước thải chứa nhiều chất ô nhiễm như hợp chất hữu cơ, amoni, sunfua, COD, BOD, và cặn lơ lửng. Việc xử lý nước thải ngành này không chỉ giúp bảo vệ môi trường mà còn tuân thủ các quy định pháp luật về môi trường.

2. Characteristics of Rubber Industry Wastewater

Wastewater in the rubber industry mainly arises from:

- Rubber processing (from natural rubber)

- Manufacture of rubber products (such as tires, gloves, conveyor belts…)

Main pollutants in rubber wastewater:

- High BOD, COD (due to containing many organic compounds from rubber latex)

- Ammonium (NH4+) and Nitrate (NO3-) from protein decomposition

- Suspended solids (TSS) from rubber residue

- Sulphide compounds (H2S) cause bad odors

- Cleaning chemicals, coagulants

3. Wastewater Treatment Technology

Similar to other wastewater groups, rubber wastewater treatment technology applies the following treatment methods:

3.1. Mechanical Treatment

- Coarse Filtration: Removes large solid impurities

- Primary Sedimentation: Helps remove suspended solids in wastewater

- Flotation: Removes grease and small suspended particles

3.2. Chemical and Physical Treatment

- pH adjustment: Use NaOH or HCl to neutralize pH

- Flocculation – Flocculation: Use alum or polymer to precipitate dirt

- Foam separation and deodorization: Use activated carbon or strong oxidizing chemicals

3.3. Biological Treatment

- Anaerobic treatment (UASB, Biogas): Decomposes high concentrations of organic compounds, creating biogas

- Aerobic treatment (SBR, MBBR, Aerotank): Uses microorganisms to decompose COD, BOD.

- Biofilter: Helps effectively treat remaining organic pollutants

3.4. Tertiary Processing

- Disinfection with Chlorine, Ozone or UV

- Adsorption with activated carbon to remove trace contaminants

- Reuse of treated water to reduce freshwater consumption

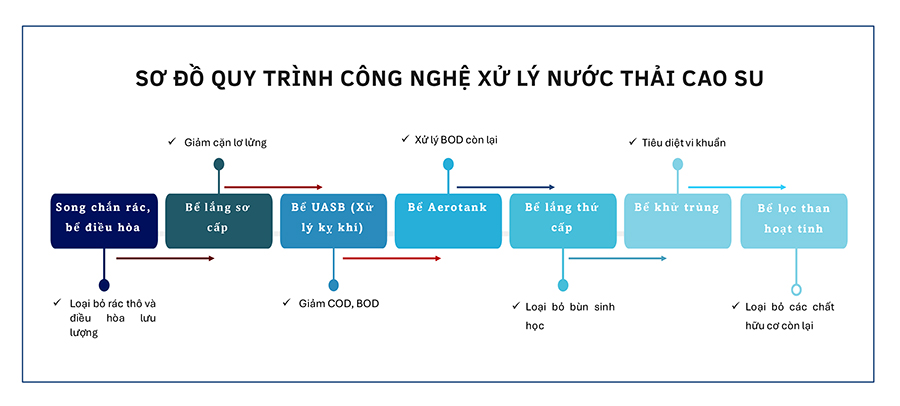

4. Rubber Wastewater Treatment Process

Depending on the specific properties of each type of rubber wastewater, there will be a suitable technological process. Normally, a typical wastewater treatment system for this industry will include the following steps:

Step 1: Trash screen, equalization tank → Remove raw trash and regulate flow

Step 2: Primary sedimentation tank → Reduce suspended solids

Step 3: UASB tank (Anaerobic treatment) → Reduce COD, BOD

Step 4: Aerotank tank (Aerobic treatment) → Treat remaining BOD

Step 5: Secondary sedimentation tank → Remove biological sludge

Step 6: Disinfection tank → Kill bacteria

Step 7: Activated carbon filter tank → Remove remaining organic substances

5. Effective Rubber Wastewater Treatment System

Some rubber wastewater treatment technology systems are being applied:

- MBBR technology: Using microbial media to increase treatment efficiency

SBR technology: Cyclic treatment helps save space

RO technology (Reverse Osmosis): Used for factories that need to reuse water

6. Benefits of Rubber Production Wastewater Treatment

✅ Reduce environmental pollution, protect ecosystem

✅ Compliance with environmental laws

✅ Utilizing biogas from anaerobic treatment process

✅ Reduce water treatment costs by reusing water

7. Conclude

Wastewater treatment in the rubber industry is an urgent requirement to protect the environment and comply with legal regulations. Applying appropriate treatment technology will help businesses minimize negative impacts on the environment. At the same time, optimize operating costs, improve production and business efficiency.

👉 Contact now to get advice from TVTS on the most effective and economical wastewater treatment solutions!