Nội dung

1. Wastewater treatment technology in containers

Container wastewater treatment systems use many modern technologies to ensure high treatment efficiency. Flexibility, high durability and suitability for each type of wastewater. Below are some popular technologies applied:

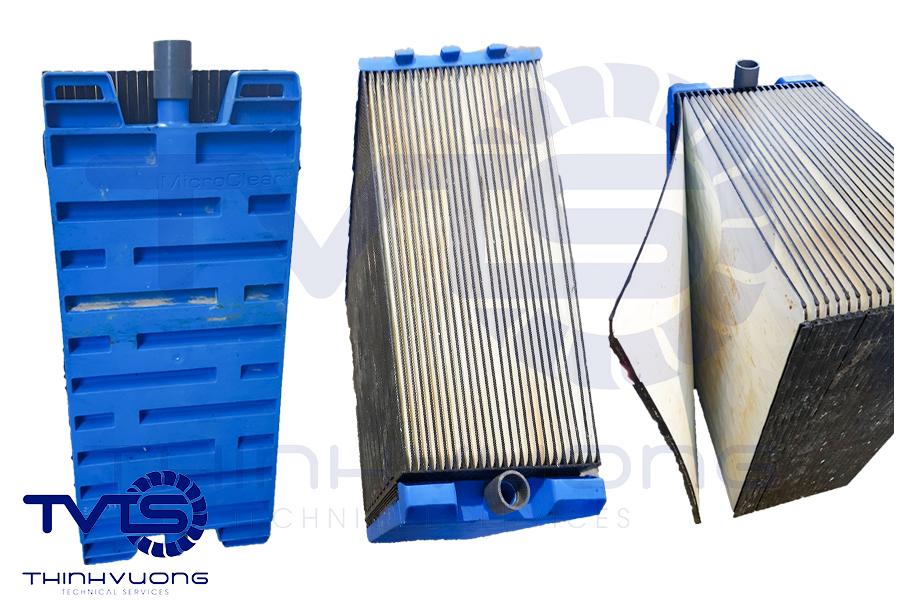

1.1 MBR (Membrane Bioreactor):

Combining microorganisms and membrane filters, effectively removing pollutants and producing high-quality output water.

1.2 MBBR (Moving Membrane Biofilter):

Using biological media helps increase microbial density, improving treatment efficiency without increasing tank area.

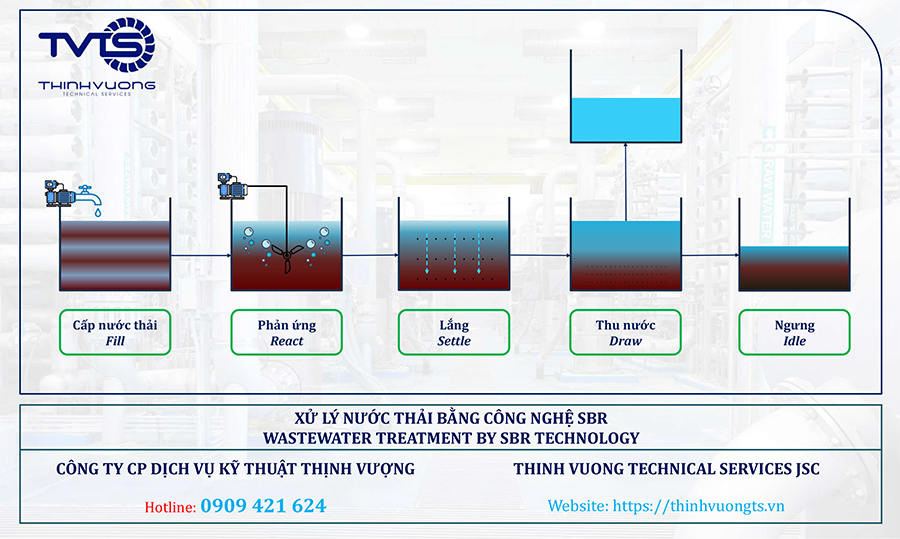

1.3 SBR (Batch Treatment):

The system operates in cycles, helping to better control the treatment process and reduce sludge.

1.4 RO (Reverse Osmosis):

Advanced filtration technology almost completely removes impurities, suitable for wastewater requiring reuse.

1.5 Evaporation and concentration technology:

Suitable for wastewater with high pollution load, helps to separate water and recover solids.

2. Process of designing and manufacturing container wastewater treatment systems at TVTS

At TVTS, the process of designing and manufacturing container wastewater treatment systems is carried out according to standard steps to ensure quality and operational efficiency:

2.1 Step 1: Wastewater survey and assessment

TVTS engineers collect samples and analyze wastewater characteristics to select appropriate technology. In addition, it is possible to rely on the results of previous analysis from customers. From there, propose appropriate technology for investment and operation problems.

2.2 Step 2: System design

Based on the survey results. The technical team will develop a system design plan, including treatment modules, reactors, piping systems, electricity and control systems.

2.3 Step 3: Production and assembly

The system is installed and completely manufactured in containers. Test the evaluation standards for durability, pressure resistance, and maximum allowable capacity. Ensure technical standards before putting into operation.

2.4 Step 4: Inspection and trial operation

Before handover, the system is tested to check the processing performance and adjust if necessary.

2.5 Step 5: Installation and user manual

TVTS transports and delivers goods to customers. Supports customers in installation at the requested location and instructs on how to operate and maintain the system.

3. Container wastewater treatment system by industry

Each industry has different wastewater characteristics, requiring appropriate treatment solutions:

Textile dyeing:

Apply MBBR technology combined with physical chemistry to treat color and organic substances.

Food:

Use MBR to remove grease, organic residue, ensuring output water meets standards.

Medical:

SBR technology combined with disinfection helps remove bacteria and toxic chemicals.

Chemical:

Use RO system to remove heavy metals, toxic organic compounds.

Seawater and fresh water:

RO system combined with multi-level filtration helps treat seawater into fresh water, suitable for islands, drilling rigs, and maritime.

Hazardous wastewater and leachate:

Apply evaporation, concentration or physical-chemical coagulation technology to reduce pollution and recover clean water.

In addition, container water treatment systems are also widely used in many other industrial and civil sectors such as water treatment for production, drinking water, electroplating wastewater, tanning, water reuse, ZLD, … container water treatment systems

Container wastewater treatment system at TVTS

The container wastewater treatment system at TVTS is designed with modern technology, suitable for many industries. Thanks to the standard production process, businesses can be assured of the treatment efficiency and stability of the system. With flexibility, easy transportation and quick installation, this is the optimal solution to help businesses be proactive in wastewater treatment, complying with international environmental standards.