TVTS is the exclusive representative and distributor of PFRO ROCHEM membrane technology in Vietnam.

Nội dung

1. Introduction to PFRO ROCHEM membrane technology

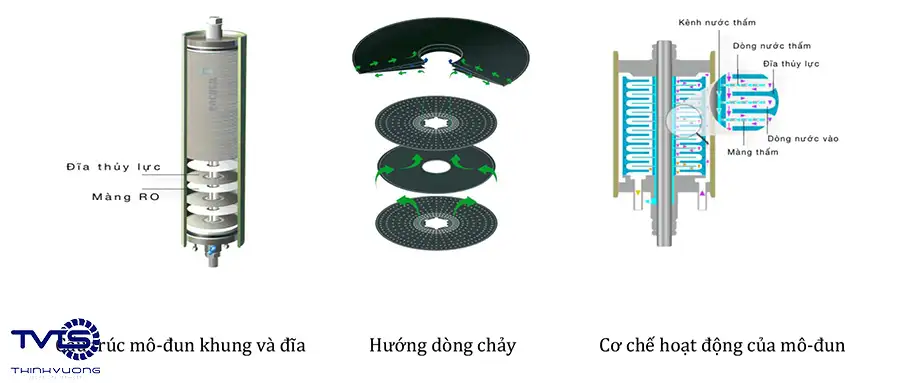

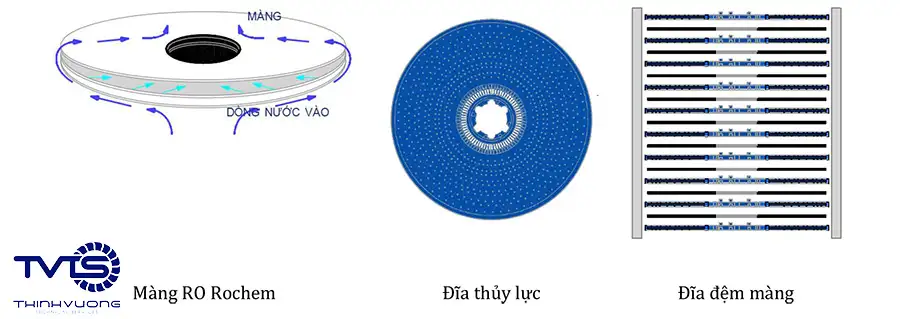

ROCHEM’s RO membrane module uses a specialized RO (Reverse osmosis) membrane in wastewater filtration. The PFRO model is an RO membrane module with a disc-shaped filter membrane. The design shows a tube module structure combined with open channels and vortex flow.

2. Characteristics in the structure of PFRO membrane module

- The modular structure combines an interwoven membrane and disc arrangement. Creates a continuous flow (open channel), thereby reducing the requirement for the pretreatment system and limiting clogging.

- The disc structure has many details that disturb the water flow to the maximum. Helps prevent scale formation on the membrane as well as increase the efficiency when cleaning.

- The modular structure helps separate the clean water channel and the sludge water channel. And all the membrane-disc designs that make up the module allow operation at high pressures up to 120bar.

- The PFRO module is designed so that the wastewater moves horizontally across the module instead of vertically. This creates short flows along the surface of the RO membrane. These short flows cause disturbance and minimize clogging.

The above special designs make a difference in the application of ROCHEM RO membrane modules. Minimize the requirements for the pre-treatment system and simplify the operation. Shown in the limit indicators for the wastewater inlet to the ROCHEM RO system.

2.1 Comparison table with traditional membrane modules:

| Target | Rochem RO membrane module | Other RO membrane modules |

| Sludge density index of wastewater | SDI < 20 | SDI < 5 |

| Turbidity of wastewater | Turbidity < 15 NTU | Turbidity < 0.1 NTU |

| Suspended solids | TSS = max 1000 ppm | TSS < 50 ppm |

| Total dissolved solids | TDS < 42.000 ppm | TDS < |

| Salinity | Can operate for water with salt concentration ranging from 2000 – 32000 ppm without changing the structure | Can only operate effectively for water with a fixed salt concentration according to the system design or at a lower level |

| Anti-clogging ability | Less membrane fouling due to the module being designed with open channels and the swirling flow formed within the module | Susceptible to membrane clogging, causing reduced output efficiency as well as requiring high and frequent membrane cleaning and replacement costs. |

| Water inlet channel | Open channel

1 mm |

3 – 7 micron |

3. Operating mechanism of Rochem PFRO membrane module in wastewater treatment

Each module consists of a stack of ABS hydraulic discs, which are connected together. A series of internal chambers are formed between the two hydraulic discs. Each chamber contains two sides of the Rochem-RO membrane.

The wastewater is introduced into the module’s pressure vessel via the inlet water pipe. The wastewater then flows down the passage between the disc stack and the pressure vessel. At the end of the flange, the wastewater passes through 8 pipes, allowing the wastewater to enter a holding chamber (open channel) below the last hydraulic disc. From this holding chamber, the wastewater passes through the ports/slots in the bottom hydraulic disc and flows over the surface of the membrane pad until it passes through the ports/slots of the next hydraulic disc.

Wastewater is prevented from escaping from the pressure vessel by 2 rubber seals attached to the upper and lower flanges.

As the wastewater flows through the membrane seal, “pure water” permeates through the membrane and is carried to the module’s clean water channel. Wastewater is prevented from flowing into the clean water channel by rubber seals attached to the hydraulic discs.

As the clean water is gradually separated from the wastewater stream, the wastewater will gradually become more concentrated with dissolved solids & organics and become a concentrated stream flowing to the concentrated flow channel.

The PFRO module can be installed and operated within 1 hour. Easy to clean and maintain.

4. Some PFRO membrane models

PFRO membranes have two main product lines: conventional PFRO membranes and high-pressure PFRO membranes. The technical specifications of PFRO membranes are shown in the following table:

| Specifications | PF 10994 | PF 10994HP (High pressure) |

| Operating pressure | 90 bar | 120 bar |

| Input flow | 0.4 – 1.2 m³/hour | 0.4 – 1.2 m³/hour |

| Operating temperature | 40˚C | 40˚C |

| Operating temperature limit | 50˚C | 50˚C |

| Dimensions (LxD) | 1000 mm x 214 mm | 1000 mm x 214 mm |

| Membrane area | 7.5 m2 | 7.5 m2 |

| Weight (operating) | 36kg | 36kg |

| Membrane testing conditions | NaCl 2,000mg/l

Pressure 225 psi (15.5 bar) |

NaCl 32,000mg/l

Pressure 800 psi (55.2 bar) |

For more information about the product. Please contact the TVTS hotline, we will discuss the issues you need help with. At TVTS, we have a small capacity, portable ROCHEM RO membrane system called a pilot. The product serves to demonstrate the water treatment efficiency of the technology right at the customer’s factory.

Thank you very much!