In the field of wastewater treatment, products, technologies and wastewater treatment methods are always interested and focused. TVTS has more than 10 years of experience in researching and applying technologies in the field of water and wastewater treatment. Technology cooperation with many experts and suppliers from countries such as Germany, USA, Japan, Korea, Singapore, China, India, …

We are confident in mastering water and wastewater treatment technologies. To provide water and wastewater treatment solutions, water reuse, water circulation, …. And the most suitable cost-saving solutions for your factory.

1. Overview of wastewater treatment methods and technologies

Wastewater treatment technology is any method, process or equipment used to remove pollutants from water and wastewater. The purpose is to clean water and/or reuse water. Thereby minimizing the impact of wastewater on the environment and human health.

Wastewater treatment methods can include mechanical, chemical, biological or a combination of methods. To remove pollutants such as organic compounds, inorganic compounds, bacteria, viruses, suspended particles, and other toxic substances ….

Here are some basic methods in wastewater treatment:

2. Wastewater treatment by physical methods

Wastewater treatment by physical methods is the process of removing pollutants from wastewater through physical treatment methods. Some physical treatment methods are mentioned as:

- Mechanical filtration

- Settling method

- Mixing

- Deodorization

- Combustion method

Physical methods in wastewater treatment can be used independently. However, they are often combined with chemical and biological methods to increase the efficiency of the treatment process.

2.1 Wastewater treatment by mechanical methods

What are we interested in mechanical treatment?

Mechanical methods, also known as filtration. It is a wastewater treatment method based on the principle of separating solid particles and liquids based on their size and physical properties.

Wastewater treatment filtration equipment by mechanical methods such as: RO, NF, UF membrane technology, primary filters, sand drum filters, material filters, filter screens, trash racks, …. The filtration system helps remove suspended particles and solids from wastewater.

3. Chemical methods of wastewater treatment

Chemical methods or chemical treatment are methods that use chemical agents to chemically transform pollutants in wastewater. Create products that are easy to treat or partially or completely treat pollutants in wastewater.

Wastewater treatment by chemical methods often uses chemical agents such as chlorine, ozone, or fluorine compounds to disinfect, oxidize or precipitate pollutants.

Methods of wastewater treatment by chemical methods are mentioned, such as:

3.1 Wastewater treatment by oxidation method (Oxidation method)

The oxidation method is a process in which a pollutant in wastewater is oxidized by strong oxidants. This process transforms organic or inorganic substances into less toxic compounds, or even completely harmless products such as CO₂ and H₂O.

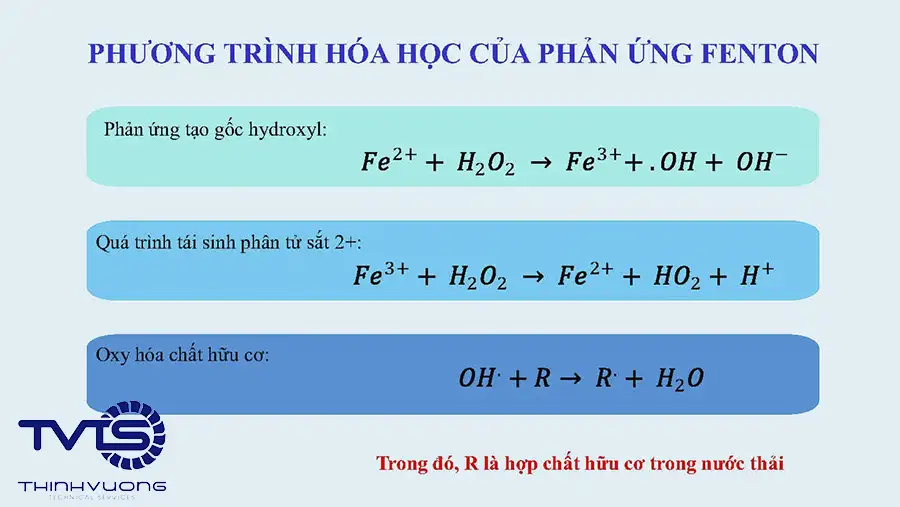

A typical oxidation method in wastewater treatment is the Fenton process, also known as Fenton technology or Fenton method.

3.1.1 Fenton reaction in wastewater treatment

The Fenton reaction is an advanced oxidation process used in wastewater treatment to decompose difficult-to-decompose organic compounds. This reaction is based on the use of hydrogen peroxide (H₂O₂) and iron ions (Fe²⁺) as catalysts to generate hydroxyl radicals (•OH), which are strong oxidizing agents.

Fenton reaction is often applied to industrial wastewater containing many organic compounds that are difficult to decompose, especially in the chemical, textile, and paper industries.

3.1.2 Advantages and limitations of oxidation methods in wastewater treatment:

| Strengths:

Highly effective for organic compounds that are difficult to decompose. Can completely remove some toxic substances. |

| Weaknesses:

Chemical costs can be high. Some oxidizers can produce toxic byproducts if not properly controlled. |

3.2 Wastewater treatment by oxidation-reduction method

The oxidation-reduction method (redox) of wastewater treatment is a process in which two oxidation and reduction processes occur simultaneously. A substance is oxidized (lost electrons) and another substance is reduced (accepted electrons). This process is used to transform pollutants in wastewater into less toxic or easier-to-treat forms.

Commonly used oxidizing-reducing agents: Chlorine, potassium permanganate (KMnO₄), biological systems (e.g. using sulfate-reducing bacteria) or electrolytic electrodes (wastewater treatment by electrolysis).

Application: Treatment of heavy metals, organic substances containing metals, or inorganic compounds such as nitrates, nitrites, sulfates.

Typical examples of redox methods are nitrification in wastewater treatment (The reduction of nitrate (NO₃⁻) to nitrogen gas (N₂) in biological wastewater treatment) or the reduction of Cr⁶⁺ to Cr³⁺ in electroplating wastewater treatment.

3.3 Advanced Oxidation in Wastewater Treatment

Advanced Oxidation Processes (AOPs) are a group of advanced wastewater treatment processes designed to remove difficult-to-degrade organic pollutants by generating powerful oxidizing free radicals, especially hydroxyl radicals (•OH). Hydroxyl radicals are one of the most powerful oxidants, capable of breaking down the bonds of many complex organic compounds, converting them into simpler or harmless compounds such as water and carbon dioxide.

Some advanced oxidation processes are:

- Fenton Technology and Improved Fenton Process

- Ozone oxidation (O₃): wastewater treatment with ozone is an effective method for removing organic pollutants, decolorizing, deodorizing, and disinfecting. Ozone technology in wastewater treatment includes equipment such as: ozone wastewater treatment machines, …

Research and application of wastewater treatment with ozone need to pay attention to the possibility of corrosion, treatment of excess ozone, …

- Photochemical oxidation (UV/H₂O₂)

- Electrochemical oxidation

- Gamma or electromagnetic oxidation

3.4 Precipitation method

Precipitation method in wastewater treatment is the process of removing dissolved substances (usually heavy metals and some inorganic compounds) from wastewater by converting them into insoluble solid form (precipitate), then separating solid-liquid to remove the precipitate from the water.

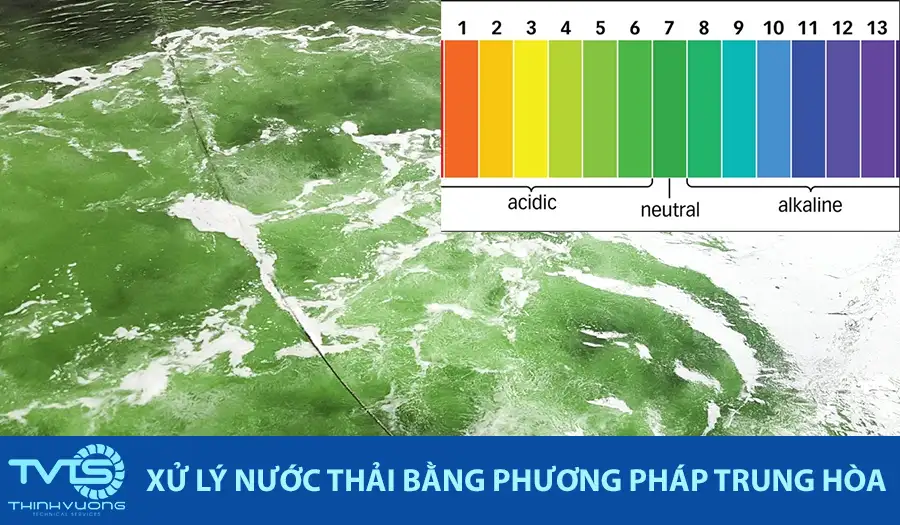

3.5 Neutralization method

Method Using chemicals to adjust the pH of wastewater to a suitable level for the next treatment process.

4. Biological methods

Biological methods of wastewater treatment or biological treatment processes are the use of biological products to convert organic pollutants into non-toxic or more easily treated substances, usually through biodegradation processes.

The biological products here can be: microorganisms, bacteria or biological processes to. These methods often focus on removing or reducing organic and chemical substances from wastewater.

Biological treatment methods are often applied to domestic wastewater treatment. And industrial wastewater treatment with high organic content.

Wastewater treatment processes using biological methods can be mentioned as: anaerobic treatment method, anaerobic method, anaerobic method, aerobic treatment method, or biofilm treatment.

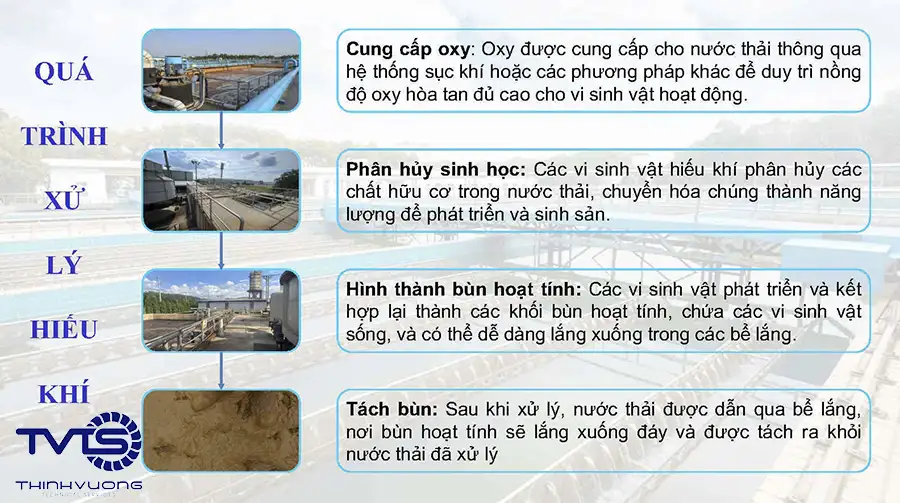

4.1 Aerobic wastewater treatment method

Aerobic wastewater treatment is a process in which microorganisms use oxygen to decompose organic compounds into final products such as carbon dioxide (CO₂), water (H₂O), and biological solids (activated sludge).

Some common aerobic wastewater treatment processes and combined aerobic wastewater treatment:

- Aerotank (Activated Sludge Process):

- Oxidation Ditch:

- SBR (Sequencing Batch Reactor):

- Biofilter:

- Membrane Bioreactor (MBR):

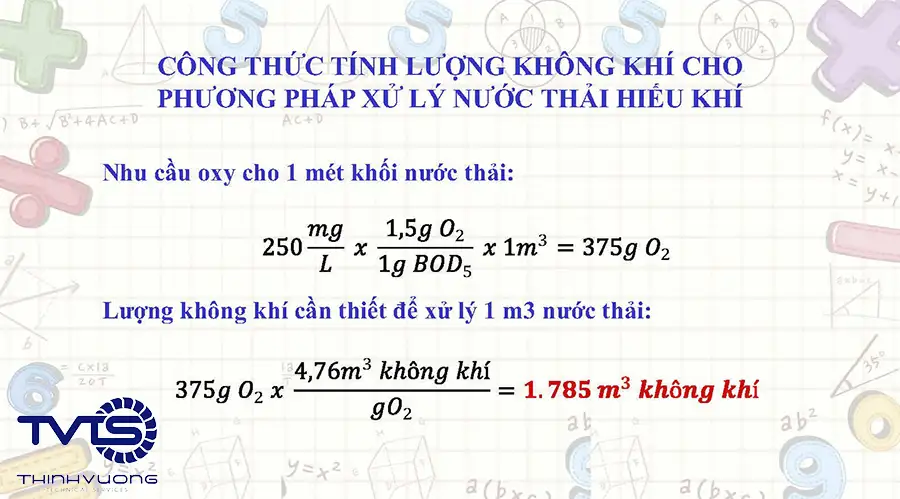

Aerobic wastewater treatment requires the amount of air needed to treat 1 m3 of wastewater, calculated by the following formula:

The amount of air required to treat 1 m³ of wastewater with a BOD₅ of about 250 mg/L by aerobic methods can be estimated at about 1,785 m³ of air.

Note: the actual amount of air may vary based on the performance of the aeration system and other specific conditions.

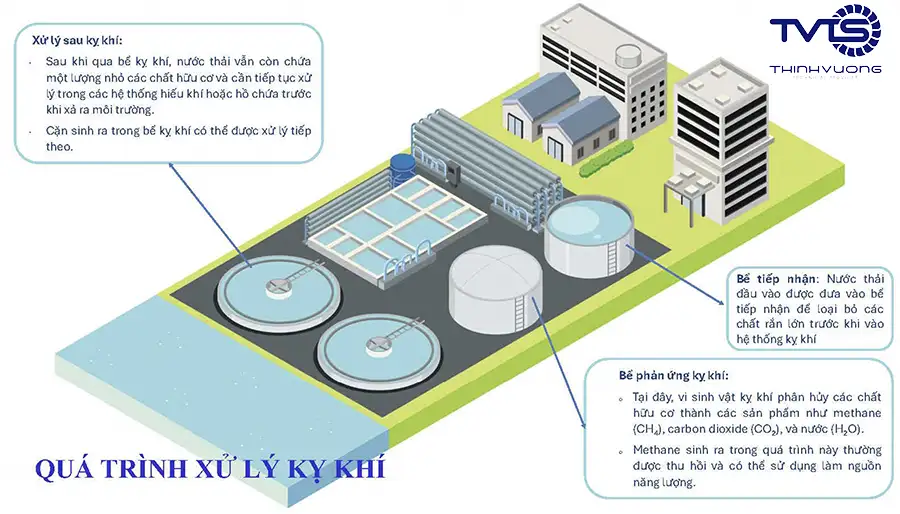

4.2 Anaerobic water treatment method

Anaerobic wastewater treatment is a process that uses microorganisms to decompose organic matter in wastewater without the presence of oxygen. This method is often applied in the treatment of wastewater with high concentrations of organic matter, such as industrial wastewater from food, beverage, paper, and textile processing plants.

Anaerobic wastewater treatment technology process:

Advantages and disadvantages of anaerobic wastewater treatment method:

| Advantage | Disadvantages |

|

|

4.3 Anaerobic wastewater treatment

Anaerobic is the treatment of wastewater in conditions of little or no oxygen, but with a small amount of oxygen supplied or indirectly present. This process often incorporates both anaerobic microorganisms and microorganisms that can tolerate low oxygen conditions

Comparison of anaerobic and anaerobic wastewater treatment methods:

| Anaerobic | Anaerobic |

| Typically applied to wastewater with medium to high organic concentrations, such as domestic wastewater or from some light industries | Applicable to wastewater with very high organic concentrations, such as wastewater from the food industry, beer production, or paper processing plants. |

4.4 Wastewater treatment with molasses

Molasses in wastewater treatment is a method of using molasses (a by-product of sugar production) as a carbon source for microorganisms.

5. Combined wastewater treatment methods

Combined wastewater treatment is the combination of mechanical, chemical and biological methods to increase the efficiency of treatment and remove pollutants from wastewater.

Combined wastewater treatment methods such as:

5.1 Electrochemical wastewater treatment method:

Electrochemistry is the process of using electric current to create direct chemical reactions in wastewater.

5.2 Electrochemical coagulation method

Electrochemical coagulation is the process of using electric current to dissolve metal electrodes (usually aluminum or iron) into wastewater. When the electrodes dissolve, metal ions (such as Al³⁺ or Fe²⁺) will be released into the wastewater. These ions will then combine with colloidal particles or small dirt in the wastewater to form larger particles, also known as “flocculation”.

5.3 Physicochemical Water Treatment Methods

Physicochemical methods in wastewater treatment are techniques that combine chemical and physical processes to remove pollutants from wastewater

Common physicochemical methods in wastewater treatment:

- Coagulation and flocculation

- Flotation

- Adsorption (chemical and physical adsorption)

5.4 Adsorption and ion exchange methods

6. Other wastewater treatment methods and technologies

Most treatment methods are based on the nature of physical, biological or chemical processes. However, there are some wastewater treatment methods that can exist in many types of processes. And in each type of process, they bring high efficiency in different cases.

Some other wastewater treatment methods that you may be interested in are:

- Wastewater Treatment with Wetlands

- Wastewater Treatment with Plants

Current wastewater treatment methods are highly effective in wastewater treatment if they are built and operated in accordance with technical standards in the drainage sector. The application of each single wastewater treatment method will be wasteful in terms of area and construction costs. The development of equipment that combines wastewater treatment methods will solve this problem very well.

7. Wastewater Treatment Equipment

What is wastewater treatment equipment?

Wastewater treatment equipment is the tools, machines, or systems used to implement wastewater treatment methods. Here are some common types of equipment in this field:

7.1 Wastewater treatment tanks

Some types of wastewater treatment tanks with specific names:

- UASB tank

- 3-chamber tank (septic tank)

- Aerotank or aerobic biological treatment tank

- Anoxic tank or anoxic biological treatment tank

- Anaerobic tank or anaerobic method (no oxygen)

- Equalization tank is a tank that regulates the flow or quality of wastewater in the wastewater treatment system.

- Vertical settling tank

- Wastewater treatment filter tank

- SBR tank: SBR is the abbreviation of Sequencing Batch Reactor. It is also known by another name, batch reactor.

- Oil separator and grease separator

- Pretreatment tank: includes tanks in the wastewater treatment process before the water enters the membrane filtration system or evaporator.

Wastewater treatment tank construction is the work of designing, preparing the construction site and completing the construction of a tank system belonging to a comprehensive wastewater treatment system.

The process of constructing a wastewater treatment tank can be complex and requires expertise and high technical skills from contractors and engineers. With experience in implementing many wastewater treatment systems in Vietnam, TVTS can advise and quote a wastewater treatment tank suitable for the wastewater treatment system for your factory.

7.2 Wastewater pump, indispensable equipment in the wastewater treatment process

Pumps are commonly used in wastewater treatment. Used to pump wastewater from one tank to another. Helps wastewater move throughout the system. Some common types of wastewater treatment pumps: Submersible pumps, screw pumps, centrifugal pumps, diaphragm pumps, etc.

In addition, pumps are also used to increase water pressure into membrane systems, carry out the filtration and wastewater treatment process.

7.3 Wastewater treatment tanks

Wastewater treatment tanks are designed to perform different processes, including: sedimentation, filtration, biological treatment and chemical treatment. Some commonly used tanks are:

– Composite wastewater treatment tanks

– Chemical tanks

– Inlet wastewater tanks

– Wastewater tanks perform functions that replace wastewater treatment tanks. (Filter tank, settling tank, earotank tank, anoxic tank, …).

7.4 Sludge press for wastewater treatment

Sludge press is used to reduce the volume and moisture of sludge during wastewater treatment. Thereby reducing the cost of transporting and handling sludge. Some types of sludge presses such as:

– Plate and frame sludge press

– Belt sludge press

– Screw sludge press

– Centrifugal sludge press

7.5 pH adjustment system

Used to adjust and maintain the pH of wastewater within the ideal range to optimize the treatment process.

7.6 Control and monitoring equipment

Including measuring devices such as pH sensors, pollution level sensors, etc. In addition, there are automatic monitoring and control systems to monitor and adjust the wastewater treatment process.

7.7 Some modern wastewater treatment equipment

With the development of science and technology. Equipment in the field of water and environmental treatment is also developing in parallel. New inventions and applications are also gradually becoming popular due to the efficiency they bring. Some notable wastewater treatment equipment today, such as:

- RO membrane module

- UF, NF, MF membrane

- Evaporators: or also known as vaporizer, evaporator, liquid concentrator.

- Crystallizers

- Sludge dryer

Wastewater treatment equipment and technology will be selected based on the scale and nature of the project. To ensure the wastewater treatment system operates effectively, wastewater is thoroughly treated. Technicians and contractors in the field of wastewater treatment need to have the best plans and designs. From there, create products with the highest treatment efficiency.

We always organize tours of the wastewater treatment system for customers. From there, customers have a basis to evaluate and judge the quality of products and services provided by TVTS.

REGISTER FOR TOUR by leaving information on the webform. Or go to the contact section with the purpose of visiting the wastewater treatment system.

Sincerely thank you!