The process of hazardous waste and hazardous wastewater treatment is very strictly and rigorously managed. To better understand what hazardous waste is? How to identify and classify waste properly? And what is the process of treating hazardous waste and wastewater in industry? We will learn about this topic in the following article!

1. Hazardous waste and things to note about hazardous waste

1.1 What is hazardous waste?

Hazardous waste is waste that can potentially cause harm to human health and/or the environment. They contain toxic components, radioactive substances, infectious pathogens, are flammable, explosive, corrosive, toxic or have other hazardous properties. (Refer to the Law on Environmental Protection 2020, at Clauses 18 and 20, Article 3)

Hazardous waste can exist in solid, liquid, gaseous or other forms. This waste is generated from living, production, manufacturing, assembly activities, etc.

1.2 Regulations on transportation, storage and treatment of hazardous waste

Regulations on hazardous waste management in Vietnam are in accordance with the provisions of Article 83, Law on Environmental Protection 2020.

1.3 Methods of transporting hazardous waste

When transporting hazardous waste, it must be contained in equipment, tanks and transported by specialized vehicles. Move safely from the waste generation area to the hazardous waste treatment facility.

In addition, vehicles transporting hazardous waste must be installed with positioning devices; move on the correct route and time as prescribed.

1.4 Regulations on units and subjects transporting hazardous waste

Individuals and organizations responsible for transporting hazardous waste are required to have:

– Specialized means of transport.

– Collection, packaging and loading equipment in accordance with technical requirements in applicable standards and regulations.

1.5 Regulations and instructions on hazardous waste management

– Each type of waste must be stored separately according to the type that has been studied and regulated.

– Hazardous waste must be kept separately, with appropriate storage equipment. Do not mix with other waste.

– Do not burn or self-treat waste that emits smoke, dust or leaks hazardous liquids into the surrounding environment.

– Storage is carried out for a period of time in accordance with the provisions of law.

1.6 Some notes on hazardous waste treatment according to Vietnamese state regulations

Hazardous waste must be treated with appropriate technology and meet the regulations under the Law on Environmental Protection 2020, Clause 1, Article 84. Hazardous waste treatment facilities must meet a number of requirements, such as:

– Licensed by a competent state agency regarding the factory area, travel route, technological process and treatment method.

– Ensuring safe environmental operation according to regulations.

– Hazardous waste treatment technology must be assessed by a specialized assessment council. Encourage the application of modern technologies, environmental protection, treatment technology combined with reuse and energy regeneration.

– Have an environmental license.

– Personnel in charge must be well-trained, have a degree in environmental science or equivalent field. Have a certificate of monitoring and managing waste treatment according to the provisions of law.

– Operation process of hazardous waste treatment system to ensure occupational safety and hygiene and fire prevention. Appropriate technologies, equipment and means.

– Develop an environmental safety and hygiene management plan, including: (1) Pollution control and waste management; (2) Occupational safety and hygiene; (3) Prevention and response to environmental incidents; (4) Periodic training and coaching; (5) Environmental pollution monitoring; (6) Evaluation of treatment effectiveness; (7) Pollution treatment plan, environmental improvement, and landscape restoration after use.

– Deposit for environmental protection according to the Law on Environmental Protection 2020, Article 137 in case the hazardous waste management unit has a landfill.

2. Overview of hazardous wastewater

2.1 What is hazardous wastewater?

Hazardous wastewater is hazardous waste in liquid or semi-liquid form. They are generated from production and business processes that use toxic substances. Including:

- Rubber Manufacturing

- Welding, Plating, Metals

- Automobile Manufacturing

- Electronic Circuit Board Manufacturing

- Chemicals

- Oils and Greases

- Solvents

- Medical Waste

- Batteries and Accumulators

- Radioactive Waste, …

2.2 Regulations on hazardous wastewater treatment

Regulations on management, treatment and assessment of hazardous wastewater quality comply with national technical regulations on industrial wastewater – QCVN 40:2011 BTNMT. In addition, it is necessary to comply with other local regulations, the Department of Natural Resources and Environment manages the area where the hazardous wastewater treatment plant operates.

3. Common methods of hazardous wastewater treatment today

Some common methods of hazardous wastewater treatment today are:

- Incineration of hazardous waste and wastewater: This method is currently more suitable for waste than wastewater.

- Phương pháp chôn lấp: phương pháp này được thực hiện từ rất lâu đời, khá phổ biến và mang lại nhiều hiệu quả. Tuy nhiên, quỹ đất đang dần cạn kiệt, quá trình chôn lấp sản sinh ra nước thải nguy hại. Nước thải này thuộc loại khó xử lý và cần một quy trình xử lý phức tạp.

- Physical membrane filtration method: using RO reverse osmosis membrane for hazardous wastewater treatment. The treatment method produces clean water that meets the prescribed discharge standards. However, it also produces a product that needs further treatment, which is the concentrated stream after RO. This water stream has a very high concentration of substances and is usually buried, burned or treated using evaporation technology.

- Evaporation method: This method provides high treatment efficiency but has high initial investment costs.

4. Hazardous industrial wastewater treatment process

Based on the experience of completing many hazardous wastewater treatment projects, difficult wastewater in Vietnam. We recommend that readers refer to the hazardous industrial wastewater treatment technology process applied at the Green Star factory. The largest hazardous waste treatment plant in the North, Vietnam.

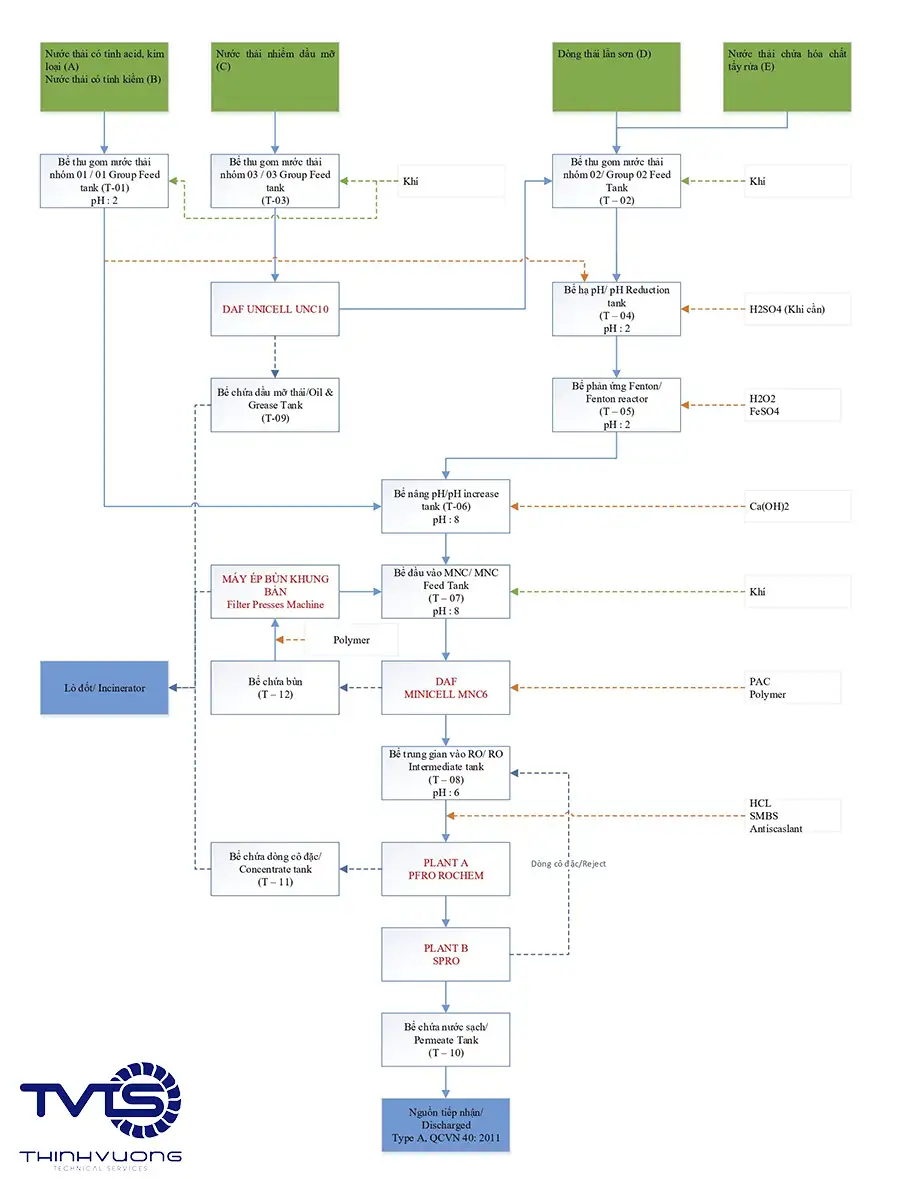

4.1 Technological process block diagram

4.2 Schematic description of the technological process block

4.2.1 Pretreatment of wastewater

Acid wastewater with low pH, metal and alkaline wastewater with high pH (and residue) are collectively referred to as group 1 wastewater. Group 1 is treated by pH adjustment, then treated by flocculation.

Wastewater containing cleaning solutions and organic and inorganic chemicals and paint-contaminated wastewater are collectively referred to as group 2. Group 2 is treated by Fenton’s advanced oxidation process to decompose organic compounds into forms that can be treated by flocculation and RO.

Wastewater contaminated with grease (group 3) is separated from gasoline using a DAF grease separation system, then treated similarly to group 2.

4.2.2 Treatment by coagulation-flocculation method

All types of wastewater after the preliminary treatment stage will go to the DAF Tank (T – 07). The water level sensor of the DAF Tank will control the operation. The coagulation-flocculation process will take place here.

4.2.3 Technology processing Rochem RO membrane

Wastewater from the Intermediate Tank will be pumped into the sand filter and fine filter system. To remove trash and suspended solids with a size > 10 μm. Then it is put into the system. PFRO ROCHEM by High Pressure Pump.

Wastewater after being treated by RO membrane will be separated into 2 streams. One is clean water that has been permeated through RO membrane to remove pollutants. The remaining stream is concentrated stream that collects most of the pollutants in the input wastewater.

Clean water after PFRO system is continuously quality controlled by dissolved solids concentration measuring device. And stored in clean water tank for reuse or disposal purposes.

Dòng cô đặc được lưu trữ bể bể chứa dòng cô đặc. Sau đó được đem đi đốt tại lò đốt chung với các loại chất thải rắn và bùn thải.

4.2.4 Xử lý bùn hóa lý

Sludge is pumped into the plate and frame sludge press. After being concentrated, the sludge reaches a moisture content of 60-70%. The water after separation is collected and brought to the collection tank of the wastewater treatment system.

4.2.5 Treatment results of the technological process

The clean water after treatment always meets the Vietnamese standard QCVN 40:2011/BTNMT type A. Even when the quality of the input wastewater changes continuously.

The system has the ability to withstand the load when the input wastewater flow exceeds up to 20%. It can receive input wastewater with 1.5 times higher pollution content.

4.4 Advantages of membrane technology applied in hazardous wastewater treatment process

4.4.1 Advantages of RO membrane technology in hazardous wastewater treatment.

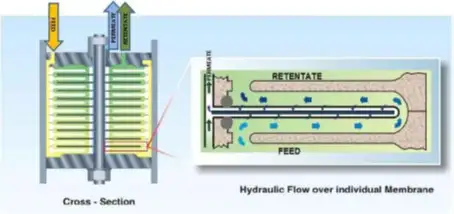

The RO Membrane Module System provided by TVTS is designed based on disc frame membrane technology. This is an RO membrane filtration system with open channel design. Allowing the system to separate waste streams with very high COD, BOD without encountering clogging problems like conventional RO membrane filtration systems.

4.4.1.1 Application for wastewater treatment

Most Rochem RO membrane systems are being applied to thoroughly treat wastewater containing high levels of COD, BOD, Nitrogen, Ammonium, etc. Applications for industries such as Landfill, Distillation, Pharmaceutical, Textile, Pesticide Production, Chemical Waste Treatment, Nuclear…

The feasibility of the membrane-disc module also prevails over other methods such as evaporation and secondary treatment.

4.4.1.2 Basic advantages of Rochem RO membrane technology

- Limit clogging.

- Technology has been proven effective worldwide.

- Can handle wastewater containing very high levels of COD, BOD, Nitrogen, Ammonium.

- Ensure optimal operating costs, low total operating costs for the entire product life cycle.

- Ensure long membrane life.

4.4.2 Advantages of hazardous wastewater treatment system provided by TVTS.

4.4.2.1 Simple operation and maintenance

The system is designed with high automation. The process is simple and effective, optimized for operation as well as maintenance and repair.

The system is capable of batch operation, with flexible operating time. The system can be temporarily stopped when all the input wastewater has been treated. And quickly restarted as soon as a new wastewater source is received that needs to be treated.

The equipment quality is very high, mostly according to EU – G7 standards. Some important items are completely constructed abroad according to European standards. Thereby limiting the risk of incidents during operation, equipment damage, etc.

4.4.2.2 Flexible design

The entire system is designed in a flexible modular style. Helps to treat many different types of wastewater at the same time while still ensuring maximum efficiency. In addition, the modular design makes it easy to accept additional waste sources beyond the original design. From there, expand the tank size, upgrade the system capacity and move the system to a new location easily.

The entire wastewater treatment system is designed to operate in batch or continuous mode. With low flow or full load: from 15 m3/day to 2000m3/day. The system is designed to operate for 20 hours. There are 2 hours of backup and 2 hours for membrane cleaning, maintenance & repair activities.

4.4.2.3 Space saving

The compact module system helps save 30-40% of space compared to traditional treatment methods.

5. TVTS provides consulting solutions, designs and completes the construction of hazardous wastewater treatment systems.

After handing over the product to the customer, in the first year of system operation, TVTS will provide support activities on a basic basis when the investor requests. TVTS’s staff is always ready to support via phone, fax, and email when the system operation has problems.

If necessary, TVTS technicians will be present directly at the construction site to handle any problems that may arise. At the same time, they will guide and train factory staff on how to fix the problem. TVTS has established a warranty program that is very suitable for customers.

TVTS warranty content

Best regards and look forward to working with you in the future!

Bài viết có sự tham khảo các tài liệu nghiên cứu khoa học của các thạc sĩ, kỹ sư đang làm việc tại TVTS; Trang báo khoa học và Pháp luật; Biên bản kiểm nghiệm kết quả thực tế tại các dự án mà TVTS đã thực hiện.

The article references scientific research documents of masters and engineers working at TVTS; Science and Law newspaper; Minutes of testing actual results at projects that TVTS has implemented.