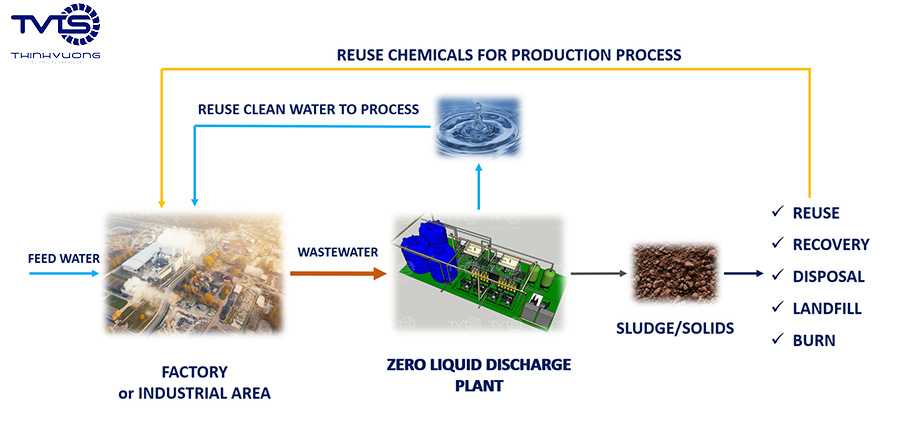

TVTS provides “Zero liquid discharge (ZLD)” technologies, processes and solutions. Applied in wastewater treatment with the purpose of completely reusing water in the production process.

What is Zero Liquid Discharge (ZLD)? Definition of ZLD

Zero liquid discharge (ZLD) means “No liquid discharge” in Vietnamese, which is a water treatment process that recovers the maximum amount of clean water in the liquid waste stream and does not create a waste stream after treatment. The aim is to reuse all generated wastewater and only produce solid waste. Therefore, the final product of the ZLD system is solid. In many cases, ZLD is often combined with the solid waste recycling process to recover products for production. ZLD from the perspective of renewable energy-oriented businesses is: water treatment; reuse; water circulation; and waste reduction. Thereby, meeting the government’s strict discharge regulations, creating a user-friendly brand.

Zero liquid discharge – ZLD regulations

According to Decree 38/2015/ND-CP on Waste and Scrap Management, our country does not have clear regulations on Zero liquid discharge – ZLD. Currently, it only regulates discharge standards for wastewater, and encourages the reuse of resources to reduce emissions and protect the environment. In Vietnam, water reuse will be based on the following standards:

QCVN 01-1:2018/BYT standard on clean water quality for domestic use

QCVN 39:2011/BTNMT National technical regulation on water quality for irrigation

QCVN 08-MT:2015/BTNMT National technical regulation on surface water quality

And some other standards, according to each water quality index suitable for the purpose of water reuse of the enterprise.

Zero liquid discharge regulations in some countries around the world

Some countries in the world

According to the environmental management newspaper, the environmental and urban page has statistics on some policies and regulations on ZLD in some countries around the world such as: UK, USA, Singapore, India, Australia, Mexico, China, etc. All have policies to encourage and support businesses applying ZLD in production.

In India

The Centralized Treatment Plant in Tiruppur was the first ZLD plant in the country in 2005. With a large scale for textile dyeing in the world, it was carried out at the request of the government.

However, most countries in the world do not have specific regulations on ZLD.

ZLD Regulations in ZDHC Organization

Particularly for the organization ZDHC (Zero Discharge Hazadous Chemical) created the Roadmap to zero program. The program leads the fashion industry to eliminate toxic chemicals from its supply chain. Create products that are friendly to workers, consumers and the environment.

ZDHC has the participation of more than 150 collaborators from major brands such as: ASOS; Adiddas; Bemberg; Advance Denim; Hayleys Fabric; Jintec; Mango; Kingdom; …

To be able to join the ZDHC organization, businesses need to meet strict regulations on toxic chemicals in: Input of the production process (input); During the production process (process); and Output (output): for both products and waste.

In which Zero liquid discharge is an assessment standard of the ZDHC organization. Here, ZLD is supported with simpler regulations than other treatment and discharge methods. Because of its obvious superior advantages in the field of textile wastewater treatment.

ZLD is the green standard that businesses, especially textile and garment businesses, always aim for. To reduce costs, improve production capacity, and build a brand with high value for consumers.

The “zero liquid discharge” problem and the difficulties of Zero liquid discharge

Zero liquid discharge brings many benefits to businesses, communities, society and the natural environment. However, zero liquid discharge wastewater treatment solutions are facing many difficulties in entering manufacturing plants. For example:

- There are no specific regulations, nor policies to support and encourage the reuse of wastewater. Currently, there are still some places that prohibit the reuse of water in the production of consumer goods. There should be additions and adjustments to clearly indicate the permission to reuse wastewater in production.

- People’s lack of understanding and skepticism when using recycled products. Or business owners and policy makers do not believe in the quality of water after treatment used for reuse. Leading to a decrease in business sales, from which businesses hesitate to invest in ZLD.

- Investing in ZLD system has high initial investment cost, long payback period, low ROI.

- Enterprises have not found a suitable technological process. Difficulties in controlling the quality of circulating water for the production process.

- Complex technological process, high investment and operating costs, long payback period. Beyond the capacity of small and medium enterprises.

Solutions for increasing efficiency in the circular economy and the mission of ZLD

From policies and regulations on management, treatment and reuse of wastewater. Some solutions to increase the efficiency of Zero liquid discharge wastewater treatment are proposed as:

- Evaluate the flow, capacity, and stability of water for reuse. Reserve clean water for production in case of an incident.

- Diversify water sources for production to reduce dependence on a single source. Save water in production, reduce water usage.

- Encourage industries to participate in water reuse projects. There is a fund to support manufacturing enterprises applying ZLD. Thereby promoting manufacturing plants to follow the progress of society.

- The State has preferential policies on tax reduction or exemption for some enterprises applying ZLD.

- Understand and be more responsible for water resources. Realize the great value of water.

What is Zero liquid discharge (ZLD) system?

The ZLD system is built on a group of water treatment processes and technologies. The technologies used in conventional ZLD systems include the use of evaporators and brine crystallizers to completely separate dissolved salts from water.

The ZLD system is built on a group of water treatment processes and technologies. Technologies used in typical ZLD systems include:

- Water pretreatment (Physical, chemical, biological…)

- Ultrafiltration NF/UF/MF.

- Reverse osmosis RO

- Heat exchanger and evaporator

- Condenser, dryer, crystallizer

Zero liquid discharge ZLD Process Flow Chart

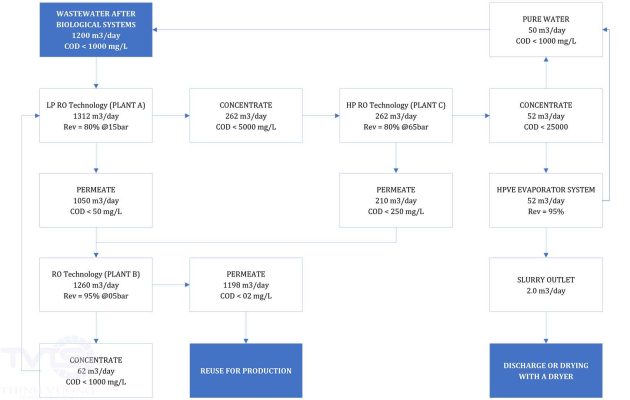

In this specific case, the factory has the following needs and current status:

– Need to completely reuse wastewater (Zero Liquid Discharge)

– The treatment efficiency of the current wastewater treatment system is not guaranteed

– Desire to minimize operating costs of the wastewater treatment system

– Increase sales and customers in markets requiring ZLD

After survey and evaluation, we propose the following ZLD technology diagram process:

Technological advantages: TVTS applies ROCHEM RO membrane technology with the ability to recover clean water up to 95%. ROCHEM RO membrane reduces pressure for the pre-treatment system with high input limit. Thereby improving the efficiency of the ZLD system, saving costs, increasing competitive advantage.

How does zero liquid discharge work? Description of ZLD’s operating process

The ZLD system operates on the principle of completely removing substances in wastewater. The remaining product after the treatment process is clean water. This water meets the set standards for partial reuse or complete recirculation for production.

The operating process of ZLD is shown on the zero liquid discharge technological process diagram as follows:

- Wastewater is preliminarily biologically treated to remove and reduce the concentration of components in the water. Meets the input standards of the RO membrane system.

- Nước thải tiếp tục đi qua hệ thống lọc RO plant A.

- After RO plant A system, the waste stream continues to go through a higher pressure RO system (RO PLANT C). The recovered clean water, if not meeting the reuse standards, will move to the low pressure RO plant B system. To improve the quality and maximize the recovery of clean water.

- After RO plant B system, clean water has met the standard for reuse, COD < 20mg/l. The concentrated stream after RO plant B system is brought back to RO plant A system for further processing.

- The concentrated stream of the RO PLANT C system is sent to the evaporation system for treatment.

- Water recovered after the evaporation system is brought back to the biological lake for circulation, and sludge after the evaporation system is treated by burying or pressing the sludge into solids.

In summary, the ZLD technology process in this situation applies two main technologies: RO reverse osmosis membrane technology and evaporation technology.

Zero liquid discharge system investment and operating costs

For the above problem, the reference cost table for the system’s capital expenditure (CAPEX) and operating expenditure (OPEX) is shown in the following table:

| OPERATING COSTS (Estimated) | |

| TOTAL OPERATING COSTS | 30,000 – 70,000 VND/M3 Clean water |

| INVESTMENT COSTS (Estimated) | |

| INVESTMENT COSTS | 20,000,000 – 100,000,000 VND/M3 Clean water |

| Payback period: about 5 years | |

Lưu ý: Chi phí sẽ thay đổi tùy thuộc chất lượng nước đầu vào, chất lượng nước đầu ra, mục tiêu tái sử dụng, công suất xử lý, …

Some technologies applied in Zero liquid discharge process

To build a ZLD system, the indispensable technology today is the evaporation equipment/system. There are many types of evaporation equipment on the market with different evaporation and water recovery methods.

Depending on the investment needs and the quality of the reused water, choose the appropriate products. Some popular evaporation equipment/systems today are:

- MEE Force Circulation Evaporation System

- MEE Flash Evaporation System

- MVR Force Circulation Evaporation System

- MVR Flash Evaporation System/Equipment

- MVR Heat Pump Evaporation System/Equipment

In addition, some technologies are applied in the zero liquid discharge process such as:

- Pretreatment processes (to reduce the concentration of dissolved solids in water)

- RO/NF/UF/MF reverse osmosis membrane technology helps to recover clean water and create a concentrated stream to the evaporation system

- Drying technology helps to crystallize the product after the evaporation system

In addition, there are many other water treatment methods applied depending on the nature of the wastewater, output quality requirements and desired investment costs.

Important techniques in zero liquid discharge water treatment process

Design, construction, equipment installation and operation of ZLD system requires specialized technical skills. Each technician needs to have enough time to be trained. Understand every detail of the system to be able to handle situations that occur during operation.

There are many technical aspects to consider when operating the ZLD system such as: physical chemistry, electrochemistry, physics, mechanics, electrical testing, programming, chemistry, biology, equipment operation, etc.

For the pre-treatment process, it is necessary to choose appropriate treatment methods. Create water quality that meets the input requirements of the RO system.

In reverse osmosis membrane technology, it is necessary to understand in detail the membrane type, membrane structure, advantages and disadvantages and actual operation of each membrane type. To have the right choice for the requirements of the ZLD system

In addition, it is necessary to understand the evaporator technology in detail because this is an indispensable factor of a ZLD system.

Evaporator technology needs to pay attention to two important factors:

- Heat Exchanger

- And Energy Recovery Methods

Zero liquid discharge system design

Parameters needed to design a ZLD water treatment system:

- Wastewater type

- Treatment capacity (m3/day.night)

- Location of construction, factory

- Construction and installation area

- For upgrading and renovation cases, it is necessary to have the current status and design drawings of the water treatment system

- Input wastewater quality analysis table

- Estimated budget

- Expected operating costs

- Equipment and material standards

In addition, when TVTS implements, it will require a survey of the actual status of the factory. If there is a wastewater source, a pilot test will be conducted. The pilot test will help to accurately assess, thereby applying appropriate treatment technology. Achieve the highest reuse efficiency.

Zero liquid discharge is applied in which manufacturing industries?

The ZLD wastewater reuse solution is and will be the leading trend in the future because of the real values and symbiotic values it brings.

All manufacturing industries that use water in their production processes can apply ZLD. For industries that use large amounts of water in production, investment will bring higher efficiency. The higher the cost of clean water and wastewater treatment costs, the more beneficial ZLD is.

Applying zero liquid discharge to some manufacturing industries such as:

- Zero liquid discharge plant for industrial wastewater treatment

- ZLD system for wastewater reuse in textile dyeing industry

- ZLD solution in turpentine production

- Water saving for cooling towers in factories with ZLD solution

- ZLD application for power plants and coal-fired power plants

- Solar energy industry applies

- ZLD method liquid discharge in aluminum coating industry

- ZLD application for brewery

- ZLD application for coffee wastewater reuse

And there are many more areas where ZLD can be effectively applied. We will update more practical applications of ZLD on the projects we carry out on our Website and Fanpage.

Zero liquid discharge system installation factory in Vietnam

We have completed many water treatment systems, such as: leachate, hazardous wastewater and difficult-to-treat wastewater groups. The system meets current discharge standards as well as allows reuse for some civil purposes.

Some pictures of the projects we have implemented

For the ZLD solution, TVTS has piloted and proposed technological processes for many projects in Vietnam. Currently, we are cooperating and implementing a number of ZLD projects. One of them is the project “Reusing coffee production wastewater with a capacity of 1200 m3/day”. With the goal of completely reusing clean water after treatment in the production process.

Zero liquid discharge ZLD market trend

Global market trends are strongly impacting the growth in demand for ZLD, including:

- Increasing urbanization, leading to excessive demand for energy and water. This in turn promotes the installation of ZLD systems.

- The population is increasing while the water supply is limited. The government needs to have policies to treat water to meet the demand.

- Strict regulations on the discharge of industrial wastewater.

- The efficiency that ZLD systems bring

According to the research report from 2015 to 2017 by “B Fortune Business Insight”, Zero liquid discharge is a potential market and will grow steadily from 2019 to 2026.

The data is collected and evaluated in the North America region (U.S and Canada); Europe (UK, Germany, France, Italy, Spain, Russia, and Eastern Europe); Some developed countries in Asia (China, Japan, Australia, …); And some Latin American countries. Showing:

- ZLD mainly applies membrane technology and thermal technology

- Strong application in the industries of Electric Power (accounting for 37.6%); Food & Beverage; Chemicals & Petrochemicals; Pharmaceuticals; Textile and Dyeing; other fields.

The global zero liquid discharge market size stood at USD 0.71 billion in 2018 and is expected to reach USD 1.76 billion by 2026.

Conclusion on ZLD market

In short, the market trend of zero liquid discharge is increasing strongly not only in developed countries but also in most countries around the world. Because of the extremely meaningful contributions that ZLD brings to humanity.

For more details on techniques, technology and the values that ZLD can bring to your business. Connect with us, to discuss what your business desires

TVTS will meet the requirements you set out with the motto of WIN-WIN cooperation. Your business development is our development.

Related Posts:

Heat Exchanger and Energy Recovery Methods in ZLD

Some Advanced Technologies Being Applied in ZLD Water Treatment Systems

ZLD Market in Asia and Vietnam

Zero Liquid Discharge System Supplier in Vietnam

News Zero liquid discharge (ZLD)

Do you need advice on technology and solutions for water and wastewater treatment?

TVTS is a contractor providing design consulting services, technological solutions, construction, equipment installation and operation of smart, automatic water and wastewater treatment systems. High water recovery capacity, improving efficiency in investment and operating costs.

Contact us